Difference between revisions of "The Nexian DMT Handbook"

m (The DMT-Nexus Extraction Handbook moved to The Nexian DMT Extraction Handbook: Proper name as of this time.) |

(→1: Extraction: Formatting) |

||

| Line 136: | Line 136: | ||

=='''1: Extraction'''== | =='''1: Extraction'''== | ||

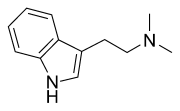

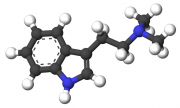

| − | [ | + | [[Image:800px-Dimethyltryptamine-3d-sticks.png|thumb]] |

| + | |||

Extraction generally refers to the process of isolating a product from a source. The basic idea is to utilize the unique properties of the product—whether reactive, electromagnetic, or otherwise structural—to draw it out of the source and into a target solvent. To accomplish this the product must either be naturally soluble in the solvent or must undergo reaction to increase its solubility. The difference between a high and low yield is firstly determined by how much more soluble the product is in the target solvent, than in its source material or solution, and secondly by how thoroughly the target solvent is mechanically brought into contact with the target solvent. | Extraction generally refers to the process of isolating a product from a source. The basic idea is to utilize the unique properties of the product—whether reactive, electromagnetic, or otherwise structural—to draw it out of the source and into a target solvent. To accomplish this the product must either be naturally soluble in the solvent or must undergo reaction to increase its solubility. The difference between a high and low yield is firstly determined by how much more soluble the product is in the target solvent, than in its source material or solution, and secondly by how thoroughly the target solvent is mechanically brought into contact with the target solvent. | ||

See also: | See also: | ||

| − | :[http://dmt-nexus.com/forum/default.aspx?g=posts&t=1085 | + | :[http://dmt-nexus.com/forum/default.aspx?g=posts&t=1085 DMT Extraction Overview] |

==='''1.1: STB Techniques'''=== | ==='''1.1: STB Techniques'''=== | ||

| Line 150: | Line 151: | ||

====='''1.1.1: Overview of Materials and Methods'''===== | ====='''1.1.1: Overview of Materials and Methods'''===== | ||

| − | {| border="1"Materials:|} | + | {| border="1" |

| + | |Materials: | ||

| + | |} | ||

| Line 169: | Line 172: | ||

====='''1.1.4: Further Elaboration and Technical Support'''===== | ====='''1.1.4: Further Elaboration and Technical Support'''===== | ||

| − | : [http://www.dmt-nexus.com/forum/default.aspx?g=topics&f=22 | + | : [http://www.dmt-nexus.com/forum/default.aspx?g=topics&f=22 Forum on the Topic of STB Extraction] |

| Line 180: | Line 183: | ||

====='''1.2.1: Overview of Materials and Methods'''===== | ====='''1.2.1: Overview of Materials and Methods'''===== | ||

| − | {| border="1"Materials | + | {| border="1" |

| + | |Materials | ||

| + | |} | ||

| Line 199: | Line 204: | ||

====='''1.2.4: Further Elaboration and Technical Support'''===== | ====='''1.2.4: Further Elaboration and Technical Support'''===== | ||

| − | : [http://www.dmt-nexus.com/forum/default.aspx?g=topics&f=21 | + | : [http://www.dmt-nexus.com/forum/default.aspx?g=topics&f=21 Forum on the Topic of A/B Extraction] |

| Line 211: | Line 216: | ||

====='''1.3.1: Overview of Materials and Methods'''===== | ====='''1.3.1: Overview of Materials and Methods'''===== | ||

| − | {| border="1"Materials: | + | {| border="1" |

| + | |Materials: | ||

* ''Acetone | * ''Acetone | ||

* Magnesium Sulfate (Epsom Salt) | * Magnesium Sulfate (Epsom Salt) | ||

| Line 219: | Line 225: | ||

** or Sodium Bicarbonate (Baking Soda) | ** or Sodium Bicarbonate (Baking Soda) | ||

* Water (Preferably Distilled) | * Water (Preferably Distilled) | ||

| − | * Powdered Botanical Material''|} | + | * Powdered Botanical Material'' |

| + | |} | ||

| Line 235: | Line 242: | ||

====='''1.3.2: Material Preparation'''===== | ====='''1.3.2: Material Preparation'''===== | ||

| − | {| border="1"'''Procedure for Rendering Anhydrous Magnesium Sulfate:''' | + | {| border="1" |

| + | |'''Procedure for Rendering Anhydrous Magnesium Sulfate:''' | ||

# spread Epsom Salt (Hydrated Magnesium Sulfate) on an aluminum foil covered pan. | # spread Epsom Salt (Hydrated Magnesium Sulfate) on an aluminum foil covered pan. | ||

# place in the oven on 400°F four about one hour, or until the salt becomes gray and ash-like. | # place in the oven on 400°F four about one hour, or until the salt becomes gray and ash-like. | ||

# place your now anhydrous magnesium sulfate into a storage container and store away from moisture. | # place your now anhydrous magnesium sulfate into a storage container and store away from moisture. | ||

| − | # if it becomes hydrated again, the process can be repeated.|} | + | # if it becomes hydrated again, the process can be repeated. |

| + | |} | ||

| − | {| border="1"'''Procedure for Rendering Anhydrous Acetone:''' | + | {| border="1" |

| + | |'''Procedure for Rendering Anhydrous Acetone:''' | ||

# pour anhydrous magnesium sulfate directly into the can of acetone. | # pour anhydrous magnesium sulfate directly into the can of acetone. | ||

# shake vigorously for an extended amount of time. | # shake vigorously for an extended amount of time. | ||

| Line 248: | Line 258: | ||

#* if it appears extremely moist, repeat the process | #* if it appears extremely moist, repeat the process | ||

#* if it appears quite dry, the acetone is ready for use. | #* if it appears quite dry, the acetone is ready for use. | ||

| − | # store away from moisture and never leave sitting with the cap off.|} | + | # store away from moisture and never leave sitting with the cap off. |

| + | |} | ||

| − | {| border="1"'''Procedure for Conversion of Sodium Bicarbonate into Sodium Carbonate:''' | + | {| border="1" |

| + | |'''Procedure for Conversion of Sodium Bicarbonate into Sodium Carbonate:''' | ||

# pour sodium bicarbonate onto a non-aluminum pan. | # pour sodium bicarbonate onto a non-aluminum pan. | ||

# place in the oven at 400ºF for one hour | # place in the oven at 400ºF for one hour | ||

| − | # place in a storage container and store away from moisture.|} | + | # place in a storage container and store away from moisture. |

| + | |} | ||

====='''1.3.3: Extraction Procedure'''===== | ====='''1.3.3: Extraction Procedure'''===== | ||

| Line 275: | Line 288: | ||

====='''1.3.4: Further Elaboration and Technical Support'''===== | ====='''1.3.4: Further Elaboration and Technical Support'''===== | ||

| − | : [http://www.dmt-nexus.com/forum/default.aspx?g=posts&t=1894&p=1 | + | : [http://www.dmt-nexus.com/forum/default.aspx?g=posts&t=1894&p=1 Discussing Alternative Spice Extraction Techniques] |

| − | + | ||

=='''2: Crystallization'''== | =='''2: Crystallization'''== | ||

Revision as of 00:23, 9 February 2009

The production and use of DMT (N,N-dimethyltryptamine), otherwise known as "Spice", is a practice that resonates strongly with the complementary qualities of ancient shamanic and alchemical spiritual practice and contemporary DIY (Do It Yourself) ethic. The production of spice is a discipline unlike most other commonly manufactured drugs, as it is not as well suited for bulk-production nor production for the purpose of sale as most well-known and intensively manufactured substances. As such, its use is generally inseparable from its production in practice and in spirit.

The production of DMT most commonly entails its extraction from botanical sources and only very rarely entails its synthesis. In this way, its production still strongly resembles its more ancient preparations by manner of brewing, a simple form of aqueous extraction still commonly performed to this day. This is the simplest and most readily administered form of extract if used as a component of a harmaloid-based preparation or -huasca brew.

Please take the time to seek further elaboration at the following resources:

Contents

- 1 0: Source Selection

- 2 1: Extraction

- 3 2: Crystallization

- 4 3: Purification

- 5 4: Administration

- 6 5: Appendices

0: Source Selection

DMT, its analogues, and other related alkaloids can be found in a wide variety of lifeforms, varying from trace amounts to considerable amounts. It is impossible, therefore, to include all of the sources from which DMT can be extracted, so the following discussion will focus primarily on the most commonly used and significant botanical sources.

0.1: Botanical Considerations

Several species of plants contain a variety of constituents apart from DMT. This consideration is of the utmost importance when selecting the source plant from which an extraction is to be performed, as it may become the determining factor in the material requirements of the extraction process. Some plants may even contain toxic alkaloids, so thorough research must be conducted prior to selection, extraction, and administration.

0.1.1: Reported Active Constituents

Mimosa Hostilis: ?

Mimosa Ophthalmocentra: 1,6% DMT in the inner rootbark (source: L. M. Batista; R. N. Almeida; E. V. L. da-Cunha; M. S. da-Silva; J. M. Barbosa-Filho. Isolation and Identification of Putative Hallucinogenic Constituents from the Roots of Mimosa ophthalmocentra. In: Pharmaceutical Biology, Volume 37, Issue 1 January 1999)

Acacia Obtusifolia: Variying reports of N,N-Dimethyltryptamine found ranging from 0.4% - 0.6% in dried bark with 0.06% reported in young phyllodes. Considered a weed, Acacia Obtusifolia is found in woodlands on Australia's eastern border from south eastern Queensland, through eastern New South Wales and scattered slightly in north eastern Victoria.

See also:

0.1.2: Methods of Refinery

Before extracting alkaloids from the variety of plants named above, one generally needs to clean and prepare the plant source, to include washing, pulverization, or any other necessary pre-treatment.

Mimosa Hostilis

[MHRB|Mimosa Hostilis Root Bark] can be acquired in different stages of preparation. Usually it is sold as whole, shredded or pre-powdered root-bark, but one may have access to the whole root—usually when harvested directly.

- The whole root must cleaned and stripped of its inner root-bark while discarding the rest of the root.

- The whole root-bark must generally be torn by hand, cut, or smashed with a blunt object prior to shredding.

- The shredded can only be used "as-is" if the pieces are small enough.

- If the pieces are too big, the alkaloids will not be as readily exposed for extraction.

- The pre-powdered can always be used "as-is".

Since each stage denotes a successively more refined preparation, the following will detail the entire process of refinery. One need only follow the procedure from its characteristic stage of refinery through to the desired stage for extraction.

Acacia Obtusifolia

[Acacia Obtusifolia] bark can be easily stripped of the trunk and branches by hand if done while still fresh. Peeling dried bark will prove to be a long tedious task.

Once peeled allow the bark to dry. The rest of the plant matter can be discarded at this point. With the help of a paper guillotine cut the dried bark into small pieces (the smaller the better).

The pieces of dried bark will now have to be grinded which can be done in a good quality blender or a coffee grinder. Allow resting periods for the blender in between grinding to ensure that the grinder does not over heat.

The grinding process allows optimum material exposure and will assist in obtaining higher yields.

0.1.3: Defatting Concerns

0.2: Vendor Considerations

- -Quality of Material

- -Privacy Concerns

0.3: Methods of Cultivation

1: Extraction

Extraction generally refers to the process of isolating a product from a source. The basic idea is to utilize the unique properties of the product—whether reactive, electromagnetic, or otherwise structural—to draw it out of the source and into a target solvent. To accomplish this the product must either be naturally soluble in the solvent or must undergo reaction to increase its solubility. The difference between a high and low yield is firstly determined by how much more soluble the product is in the target solvent, than in its source material or solution, and secondly by how thoroughly the target solvent is mechanically brought into contact with the target solvent.

See also:

1.1: STB Techniques

Considerations:

- The use of "Straight To Base" techniques requires little experience or technical know-how for beginners to approach extraction techniques. STB is best-suited for quick, non-labor-intensive, crude bulk extractions. It requires no straining or cooking but requires time for soaking and separation. STB tends to yield a greater array of botanical impurities due to its lack of straining and defatting. These techniques do however enable a more thorough exhaustion of product from the material. This technique is ideal for shredded material that requires little or no defatting.

1.1.1: Overview of Materials and Methods

| Materials: |

Methods:

1.1.2: Material Preparation

1.1.3: Extraction Procedure

1.1.4: Further Elaboration and Technical Support

1.2: A/B Techniques

Considerations:

- The use of Acid/Base techniques implies the use of "acid-cooking" the source material, straining it, and basifying the resulting strained solution. The use of an initial acid extraction facilitates the implementation of a defatting phase and generally yields a product more devoid of botanical impurities. This technique is ideal for any material that requires defatting, though defatting may not be necessary, depending on the intended method of crystallization.

1.2.1: Overview of Materials and Methods

| Materials |

Methods:

1.2.2: Material Preparation

1.2.3: Extraction Procedure

1.2.4: Further Elaboration and Technical Support

1.3: Dry Techniques

Dry techniques (drytek) evolved from and are ideally intended for the implementation of the [FASA|FASA] method of crystallization and serve as the only techniques able to implement acetone as an extraction solvent. Acetone is generally favored for its ability to extract a notably broad range of active products.

Considerations:

- The use of dry techniques requires fewer and less toxic materials than the techniques that employ aqueous phases and separatory methods. The materials required are generally of a more household nature. They are most effectively applied to powdered botanical material. Acetone is, however, completely water miscible, so proper drying procedures are of the utmost importance. This technique may or may not require the defatting of botanical materials, depending on the intended method of crystallization. Dry techniques are the youngest of the current extraction techniques though apparently sound in theory and in practice.

1.3.1: Overview of Materials and Methods

Materials:

|

Material Considerations:

- Acetone can be purchased at hardware stores but should be confirmed as pure acetone prior to purchase. Note that almost all acetone can contain up to 5% water contamination, depending on time and shelving conditions.

- In order to be utilized for extraction, sodium bicarbonate must undergo conversion to sodium carbonate.

- Lime is often found difficult to decant acetone off of and also difficult to filter out of acetone, whereas sodium carbonate is generally found more agreeable for both.

- Distilled water is preferable, as tap water almost always contains impurities that can potentially tamper with resulting yields.

- With few exceptions, the source material should be completely pulverized to a powder consistency before use, as this technique's choice of reagents are not quite capable of penetrating cell structure.

Methods:

- Extractions by dry techniques are characterized by the lack of a traditional aqueous phase in the extraction process, and instead, opting for basification within a paste which is followed by chemically drying the paste with desiccant. The process does not make use of separatory methods, and instead is characterized by it's use of dry-washing, decanting and non-intensive filtering methods. Certain materials must be rendered anhydrous prior to use.

1.3.2: Material Preparation

Procedure for Rendering Anhydrous Magnesium Sulfate:

|

Procedure for Rendering Anhydrous Acetone:

|

Procedure for Conversion of Sodium Bicarbonate into Sodium Carbonate:

|

1.3.3: Extraction Procedure

- Mix the intended base with the powdered source material at a ratio between 1:2 and 1:1.

- The product remains in its natural salt form which is generally considered to be quite free from the botanical cell structure in powdered material.

- Add only enough water to thoroughly moisten the mixture to the consistency of a paste while stirring to ensure the consistency of the mixture.

- Although this is not generally considered a traditional aqueous phase in that it is not a solution, it is an aqueous phase in that it is excessively hydrated and sufficiently aqueous to facilitate reaction.

- Allow adequate time to soak in order for reaction to occur.

- The acid component of salt-form product undergoes reaction with the base, effectively neutralizing the acid and freeing the product in its pure alkaloid form, or freebase.

- Stir in anhydrous magnesium sulfate until thoroughly dry.

- The magnesium sulfate acts as a desiccant, and that this is performed in order to prevent water contamination of the acetone.

- Add an excess of anhydrous acetone and stir thoroughly, allotting adequate time and stirring for thorough dissolution of the product into the acetone.

- The more contact allotted between the product and the acetone, the greater the saturation.

- Decant and/or filter acetone and collect, being careful not to allow any particulates into the collection vessel.

- The bases used should not harm the quality of the product, but may interfere with the accuracy of weight.

- Repeat steps 5-6 with fresh acetone until material is exhausted to satisfaction.

- Three washes is generally considered sufficient.

1.3.4: Further Elaboration and Technical Support

2: Crystallization

Crystallization is the process by which a product is isolated from a solvent. This is accomplished by either allowing the solvent to completely evaporate or by causing a precipitation to occur within the solvent, which can then be isolated from the solvent by several methods and then dried of any residual solvent.

2.1: Evaporation

In extraction, evaporation is the process by which a solvent disperses from its liquid form into the air as a vapor and a gas. When this occurs, the less volatile constituents of the solvent solution are left behind, and as such, it is a common method of isolating solutes from solvent.

Considerations:

- Many common solvents contain impurities which may not be quite as volatile as the pure solvent and may leave these impurities behind as a residue.

- Solvents often emit fumes and odors which may be hazardous to health, flammable, or may alarm those within proximity of the odor.

- Some solvents may require an excessive length of time to evaporate.

- Some solvents may absorb ambient moisture, resulting in a less expedient evaporation.

- Excessive air flow may cause the oxidization of the product.

- Solvent may become Trapped within the crystal structure of the product, resulting in a less solid and less pure product.

2.2: Freeze Precipitation

Freeze precipitation is the process by which product is isolated from a solvent through a decrease in solubility achieved by lowering the temperature of the solvent. This process generally relies on the solvent being completely saturated or super-saturated with product. Freeze precipitation is generally the fastest method by which product can be isolated immediately following extraction, but it relies on the use of only very specific solvents. This method is preferably used in conjunction with A/B and STB techniques.

2.3: Salting Methods

Salting is the process by which freebase DMT is reacted with an acid to create a salt form which is generally water-soluble. The natural form of DMT in botanical sources tends to be a salt-form, thus facilitating the simple aqueous extraction used to prepare DMT-containing brews. It is quite common to perform aqueous acid extractions from the material, however—whether for the purposes of a brew or for A/B extraction. The salt-form itself rarely lends itself to proper crystallization and usually can only be isolated as an oil unless very specific methods and materials are employed.

2.3.1: The FASA Method

The [FASA|FASA], or fumaric acid saturated acetone, method is a method employed to render [DMT Fumarate|DMT Fumarate].

Considerations:

- [DMT Fumarate|DMT Fumarate] is reportedly quite stable and resistant to oxidization or other forms of degradation. It is notably resistant to heat, and as such is able to withstand low-temperature oven-drying. Certain other related compounds, such as jungle-spice and bufotenine are also able to crystallize as a fumarate. Defatting is not required prior to employing [FASA|FASA] methods, as oils and most other impurities should not interfere with this method's procedure or the yield

- Because [DMT Fumarate|DMT Fumarate] is water-soluble, it is also well-suited for oral administration in conjunction with harmaloids, either mixed into a beverage or encapsulated.