|

|

| Line 19: |

Line 19: |

| | | | | | |

| | * Sodium Carbonate | | * Sodium Carbonate |

| − | ** washing soda, can be [[Conversion of Sodium Bicarbonate into Sodium Carbonate|rendered from baking soda (sodium bicarbonate)]] | + | ** can be [[Conversion of Sodium Bicarbonate into Sodium Carbonate|rendered from baking soda (sodium bicarbonate)]] |

| | | | | | |

| | * Razor Blade | | * Razor Blade |

Revision as of 06:09, 11 January 2010

|

Note: | This page tracks the development of amor_fati's Approach to Freebase Conversion of DMT[1]. The content is to remain accurate as such. |

Though relatively simple, the conversion of DMT fumarate to freebase tends to pose some difficulties for achieving a pure and well crystallized product. Decanting from material containing magnesium sulfate powder will often carry particulates that are not easily filtered. Evaporation can take an excessive amount of time to achieve a solid product and often doesn't result in a very solid product. This technique is intended to remedy such problems.

Nontoxic Conversion

| Nontoxic Conversion of Full-Range Fumarate Extract of Jurema to Freebase w/ Hasty Manual Crystallization

|

|

Step 1: Mix fumarate w/ sodium carbonate |

Step 2: Moisten to facilitate reaction |

| Materials Required |

|

Source Material:

- Anhydrous Salted Extract of Jurema

|

Solvents:

|

Reagents/Desiccants:

|

Equipment:

- Razor Blade

- Lab Spatula

- any similar tool will work

- Evaporation Dish

- Collection Vessel

|

|

- Mix DMT fumarate with an equal or greater amount of sodium carbonate on the evaporation dish and moisten thoroughly.

- Allot adequate time and stirring for complete reaction.

- Spread the moistened mixture evenly and thinly across the dish.

- the better spread out it is, the more likely the product will adhere to the glass, preventing it from being washed away.

- Add a minimal amount of water to dissolve the sodium carbonate and salt byproduct by tilting the dish to ensure adequate contact.

- When all visible sodium carbonate grains have been dissolved and all particulates settled, carefully decant the water into a collection vessel.

- Repeat the washing process once more with a smaller amount of water to wash off any leftover solutes.

- the collected washes may yet contain actives, so save the washes to reuse or otherwise extract from.

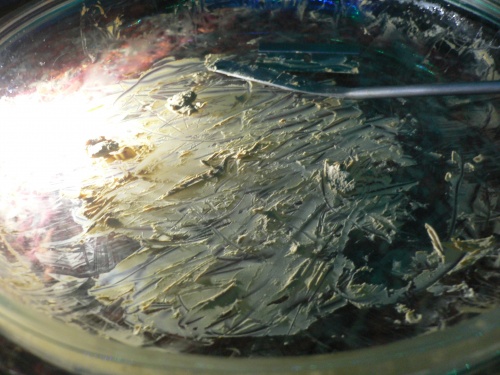

- Use a razor blade to spread the oily product across the dish in cross-hatched fashion, applying firm pressure while doing so.

- When the oil thickens to a pasty consistency, use a lab spatula repeatedly scrape up and and spread out the product until it thickens noticeably more.

- Spread the product thinly across the dish and allow to harden to a clay-like consistency.

- Store in a cool, dark place in a sealed container, preferably protected from moisture and oxygen, and handle with care and sincerity.

Step 5-6: Decant wash-water |

|

|

Step 8: Repeatedly scrape and spread |

|

Step10: Scrape up to collect |

|

Drytek Conversion

| Drytek Conversion of Full-Range Fumarate Extract of Jurema to Freebase w/ Hasty Manual Crystallization

|

|

|

|

| Materials Required |

|

Source Material:

- Anhydrous Salted Extract of Jurema

|

Solvents:

|

Reagents/Desiccants:

- Sodium Carbonate

- Anhydrous Magnesium Sulfate

|

Equipment:

- Razor Blade

- Lab Spatula

- any similar tool will work

- Dropper

- Evaporation Dish

- Reacting Vessel

- Collection Vessel

- Transfer Vessel

- Cotton Balls

- Small HDPE Bottle

|

|

- Mix DMT fumarate with an equal amount of sodium carbonate and moisten thoroughly.

- Allot adequate time and stirring for complete reaction.

- Mix in anhydrous magnesium sulfate until material is thoroughly dry.

- Prepare a small THP by cutting the bottom off a small HDPE bottle, stuffing cotton balls in the neck, inverting it and suspending it over a glass receiving vessel.

- Empty the material into THP and pour anhydrous acetone through the material into the collection vessel.

- If particulates leak through the filter, pour the acetone back into THP and repeat until no more leakage occurs and until satisfied with the level of saturation as indicated by the color of the solution.

- Pour acetone into an evaporation dish

- Continue to pull with acetone until material is apparently exhausted as indicated by a lack of coloration.

- the material can be left in THP and stored as such to be reused without removing the old material or filter.

- Evaporate acetone in a food dehydrator below 100F until sparse droplets of liquid remain.

- evaporation and crystallization can be accomplished simply by leaving the dish in a dry area for a few days, foregoing this step and those following.

- adding a small amount of acetone and even heptane when the liquid has reduced to a small puddle may hasten the evaporation process

- Use a razor blade to spread the oily product across the dish in cross-hatched fashion, applying firm pressure while doing so.

- adding minute amounts of acetone drop-wise may hasten the process.

- When the oil thickens to a pasty consistency, use a lab spatula repeatedly scrape up and and spread out the product until it thickens noticeably more.

- Spread the product thinly across the dish and allow to harden to a clay-like consistency.

- Store in a cool, dark place in a sealed container, preferably protected from moisture and oxygen, and handle with care and sincerity.

|

Appendices

Material Preparation

| Rendering Anhydrous Magnesium Sulfate

|

|

- Spread Epsom Salt (Hydrated Magnesium Sulfate) on an aluminum foil covered pan.

- Place in the oven on 400°F for about one hour, or until the salt becomes gray and ash-like.

- Place your now anhydrous magnesium sulfate into a storage container and store away from moisture.

- If it becomes hydrated again, the process can be repeated.

| NOTE |

|

| This can also be done on the stove top/oven ring, however it should be noted that as the Epsom Salt releases water it will stick to the inside of your pot but as it reaches complete dehydration and becomes grey and ash like it will unstick and become a powder.

|

|

|

| Rendering Anhydrous Acetone

|

|

- Pour anhydrous magnesium sulfate directly into the can of acetone.

- Shake vigorously for an extended amount of time.

- Allow to settle for one day.

- Observe the magnesium sulfate at the bottom of the can.

- if it appears extremely moist, repeat the process.

- if it appears quite dry, the acetone is ready for use.

- Store away from moisture and never leave uncapped.

|

| THP Approach to Rendering Anhydrous Acetone

|

|

- Prepare THP by cutting the bottom off of an HDPE bottle and stuffing cotton balls the neck.

- Fill THP with anhydrous magnesium sulfate, leaving enough room for an appropriate amount of acetone to fill.

- Pour acetone through THP until satisfactorily dried.

- Store acetone away from moisture and never leave uncapped.

|

Reference

- ↑ amor_fati's Approach to Freebase Conversion of DMT[1]