|

Note: | This page has been transcluded to The Nexian DMT Handbook under the The Machine section or other locations within or without the handbook. Please markup in consideration of this. The top section header is to remain in place as a reference for subsequent section headers and to allow easy editing directly from the handbook. |

The Machine

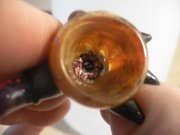

"The Machine" is essentially a glass vaporizer in which heat is meant to distribute through the pipe rather than across the glass. It utilizes a metal mesh plug inside of the pipe, on which the product is to be placed, melted and vaporized. The mesh acts both as a screen and a heat-sink, simultaneously allowing for the even heating of the product, protection from the naked flame, and prevention from inhaling unvaporized particulates. The manner of heating is likely to be conduction, as the product is known to run from the heat across the mesh until completely vaporized; however, most designs cause the product to simply run into more heat, resulting in continuous vaporization.

This method of vaporization includes the standard variations—which are essentially the simple combination of a vaporizing bowl and a vapor chamber with an inhalation nozzle—and the bubbler variations in which the vapor passes through a water heat-sink before reaching the vapor chamber and inhalation nozzle.

Material Considerations:

- Copper may gradually turn black due to the formation of Copper(II) oxide (CuO), an inert solid. This reaction and its products are not detrimental to the process of administration.

| the Improvisation of the Standard Variation

|

|

| NOTE |

|

| Though the most common and traditional glass piece used would be a small bottle with a hole drilled in the bottom, other more accessible and workable alternatives, such as bulbs or test-tubes with small holes punched in the end[1][2], dropper stems[3], or glass basters[4], among others have been reported, though vary in effectiveness, primarily due to the size of chamber and method of loading and heating.

|

|

- Obtain a glass piece with only two openings—one smaller than the other—accessing a single chamber.

- commonly by drilling or filing a hole in the bottom of a single-serving liquor bottle.

- Prepare a plug made of metal mesh by cutting a piece of an excess of the appropriate size to fit in the larger opening of the glass piece.

- Stainless steel and copper of a coarse mesh are preferable, as they do not tend to burn at the temperatures needed for vaporization.

- Using pliers to hold the cutting, use a torch to thoroughly burn off any machine oil or coatings found on the mesh.

- Perform this step until no more smoke can be observed emanating from the cutting.

- Allow to cool and roll the cutting tight enough to fit in the larger opening of the glass piece.

- The plug needs to be tight enough to suspend it in the opening but not so tight as to block air passage.

- Obtain an inhalation nozzle or mouthpiece of some kind if necessary to facilitate inhalation from the vapor chamber through the smaller opening in the piece.

- A tube or straw of some kind is the most common method.

| A Customized Design of "The Machine"[5]

|

|

|

|

|

| Notes on Administration |

|

- To load, simply place a measured dose in the chamber, on the plug and carefully melt into the plug by feathering with a flame or other heat source.

- A butane torch is generally consider to be the most effective heat-source.

|

|

|

| NOTE |

|

| Theses variations can apply to the use of a small bubbler pipes, bong-style bubblers, or improvised bubblers, though smaller bubblers are often found most preferable. The water in the bubbler acts only as a heat-sink and will not absorb a significant, if any, amount of product, as the freebase product is not soluble in water; however, the use of ice in cooling should be forgone, as it may cause the premature precipitation of product within the chamber.

|

|

| the Improvisation of the Bubbler Bowl Variation of "The Machine"[6]

|

|

| NOTE |

|

| This design differs from "the machine" slightly in that it does not consistently protect the product from open flame.

|

|

- Prepare a plug made of metal mesh by cutting a piece of an excess of the appropriate size to fit in the bowl.

- stainless steel and copper of a coarse mesh are preferable, as they do not tend to burn at the temperatures needed for vaporization.

- a thin tube of about an inch long will facilitate the most effective use

- Using pliers to hold the cutting, use a torch to thoroughly burn off any machine oil or coatings found on the mesh.

- perform this step until no more smoke can be observed emanating from the cutting.

- Allow to cool and roll the cutting tight enough to fit in the bowl.

- if using a small thin tube of mesh, stuff the end tightly in the bowl and coil loosely around the inside, leaving about a quarter inch of space between the coil and the lip.

- the plug needs to be tight enough to suspend it in the opening but not so tight as to block air passage.

| Notes on Administration |

|

- To load, simply place a measured dose directly on top of the plug and carefully melt into the plug by feathering with a flame or other heat source.

- A standard lighter will work adequately for this style of device.

|

|

|

| the Improvisation of the Machine-Style Bubbler Stem[7]

|

|

| NOTE |

|

| A design of bubbler or piece that facilitates being angled in such a way that the product can only run down toward the heat-source is preferable to ensure full dosage.

|

|

A Machine-Style Bubbler Stem seated in a bubbler.

- Prepare a glass piece to be fitted to the intake of a bubbler.

- this can be accomplished either by using a glass piece small enough to fit inside with a gasket fitted to provide a seal or by attaching the piece with a small section of tubing; traditionally, a dropper stem with the nozzle broken off and edges melted is implemented.

- Cut off a piece of the metal scrub pad, hold it with pliers, and burn with a torch under an oven hood until no more smoke is emitted.

- After it has cooled, stuff it in the larger end of the piece, and stuff it down toward the end designated for heat application somewhat tightly, and so that a part of the mesh is exposed.

| NOTE |

|

| Most designs will result in runoff if used at a downward angle, but if a straight glass piece is used, that runoff may be immediately retrievable for further administration by simply plunging the plug to one end of the piece--collecting oil--then back into place.

|

|

| Notes on Administration |

|

- To load, simply place a measured dose inside the piece and onto the plug, and carefully melt into the plug by feathering with a flame or other heat source.

- A butane torch is a preferable heat source for the operation of this piece.

|

|

|

Further Elaboration and Technical Support

- "The Machine" Article from The Entheogen Review

- "the machine" Q.'s

Reference

- ↑ "The_(mini)_Machine"_Step_by_Step_Guide

- ↑ q21q21's Test-Tube Machine

- ↑ Reintroducing My Alternative to "The Machine" by amor_fati

- ↑ New stealth bargan vapour pipe by deweeb

- ↑ My Machine by Aoutiv

- ↑ Posts Regarding Construction and Operation of a Machine-Style Bubbler Bowl by WSaged[1][2][3][4]

- ↑ The Mini-Machine Bubbler Stem