CIELO

Contents

Introduction 🙏

CIELO stands for Crystals In Ethyl-acetate Leisurely Over-the-counter.

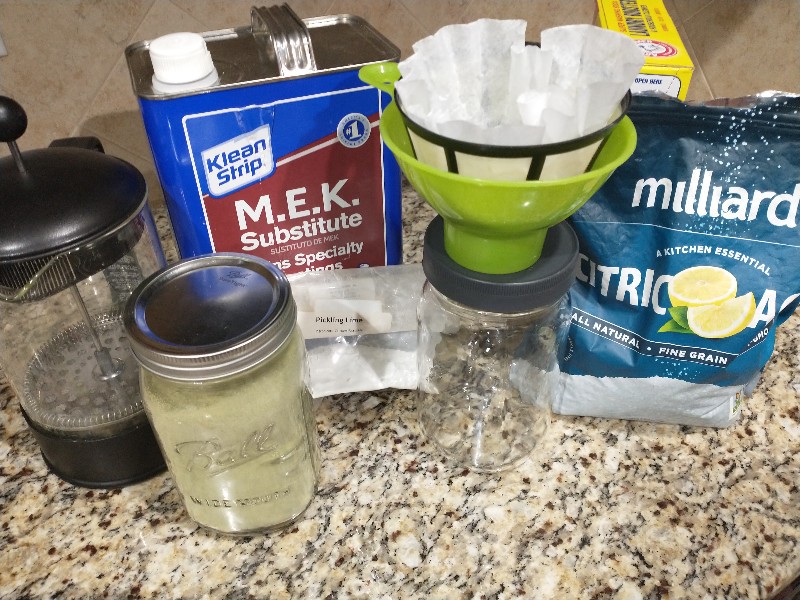

In this technique (TEK), cactus lime paste (Fig. 2) is extracted with ethyl acetate (Fig. 3). Mescaline citrate is precipitated with citric acid (Fig. 4) and collected (Fig. 5).

Thanks to everyone who contributed to this process: someblackguy, Benzyme, shroombee, Metta-Morpheus, Downwardsfromzero, Kash, grollum, Mindlusion, Doubledog, Dreamer042, merkin, Loveall, and others.

Safety ⛑️

Review ethyl acetate[1] and citric acid[2] safety information. Verify solvent MSDS, plastic compatibility, and clean evaporation.

Following this advice does not guarantee safety. It is up to each adult individual to make their own decision.

Materials 🛒

- French press (or similar ensemble)

- 300g water

- 25g lime

- 100g dry cactus powder

- 1qt ethyl acetate (also sold as "MEK substitute")

- Coffee filters, support basket, and funnel

- Quart jar

- 5g of citric acid (15g is another option)

- Washing soda and pH paper (for solvent reclaim)

Process 📜

Paste 🌵

Mix water and lime first to make milk of lime in french press (or quart jar if french press is not available). Without giving lime time to settle, incorporate cactus while mixing and continue to mix well for at least 10 minutes to a fluffy smooth paste (Fig. 2). When mixed well an airy texture usually develops. In case of doubt, mix more. This paste has the same ratios originally used in 69ron's limonene TEK [3].

Microwave option: This option breaks down chlorophyll and can make subsequent crystallization and solvent reuse easier. It is believed that this process is more robust to cactus variability. Simply microwave the paste described above in short spurts of a few minutes (watch carefully to avoid over boil), stirring frequently until 2/3 of the water (200g) evaporates. Paste will change texture through the process temporarily becoming more liquid, and later becoming loose moist fluff. With this option, the subsequent extract will be tan instead of green and will typically produce larger crystals.

Extract 👨🏾🔬

Cover paste with ethyl acetate (~150g), mix well for 60s, allow to rest for 120s and decant into quart jar through a coffee filter. Do not squeeze with the french press, its purpose is to only hold back the paste from falling into the filter and squeezing can push unwanted material into the extract. Repeat until quart jar is full (~5-6x).

Extraction should be complete in less than 30 minutes, after that amount of time the paste can begin to congeal. There is plenty of time to leisurely perform the pulls by remaining focused on the task.

Inspect extract for droplets or particles. If present, remove them. Extract needs to be clean (see Fig. 3). To be sure extract is clean, one extra pass through a fresh coffee filter after settling is recommended.

Crystalize ✨

Drop citric acid into extract and let it slowly dissolve by diffusion over time. Clouds form, followed by mescaline citrate crystals. Crystals can have different shapes and sometimes also stick to the wall looking transparent. Allow crystalization to complete undisturbed (~24 hours). Swirl extract after crystallization for several minutes to ensure all of the citric acid granules have dissolved.

Fast crystalization option: Use 15g of citric acid and continuous magnetic stirring (or continuous shaking) to both dissolve citric acid quickly and speed up crystallization. This produces a fast crystalization and minimizes crystals that are stuck to the wall. A stirring vortex will go from visible, to not visible as clouds form, to visible again as mescaline citrate precipitates. Crystals may be smaller with this approach, but the vast majority of them will still be caught by a filter in the next step.

Note: Citric acid is relatively soluble in ethyl acetate (50mg/g). A common question when mescaline citrate precipitates is how does one know that citric acid is not what is precipitating? The answer is simply that citric acid does not precipitate and stays in solution because it is bellow its saturation point. The white particles that form from the clouds are mescaline citrate and not citric acid.

Collect 💖

Catch loose crystals in a coffee filter. Rinse crystals on wall and filter with fresh ethyl acetate (~2-3x until off color is removed). Collect crystals stuck on the jar walls by dissolving them in warm water, evaporating in a shallow dish, and scraping up dry crystals. Combine with the collected crystals from the filter to obtain the final product (Fig. 5).

Yield depends on the cactus and is usually between 0.2% to 2% with ~1% being common[4]. By weight, mescaline citrate is equivalent to mescaline sulfate dihydrate and 90% as strong as mescaline hydrochloride. Approximate oral dosage recommendations can be found elsewhere[5].

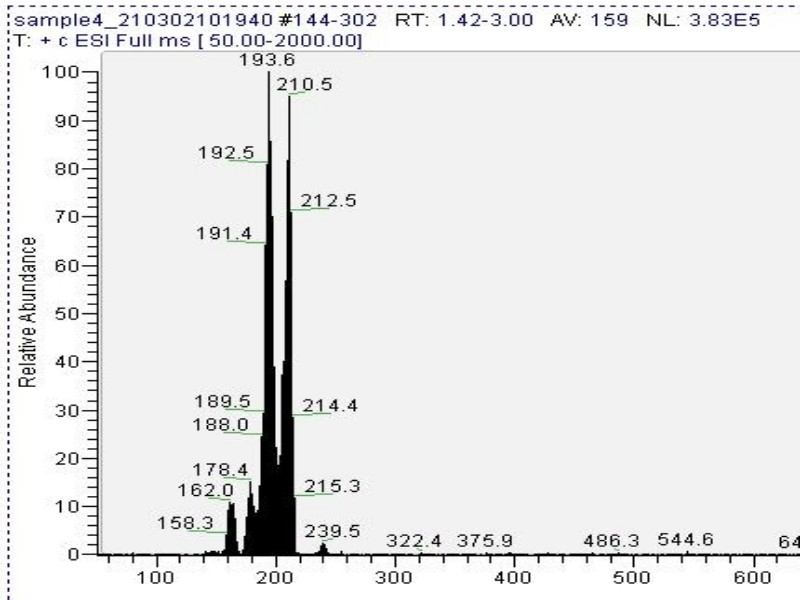

Mass spectrometry (MS) results from solaris analytical[6] indicate the product is very clean mescaline (Fig. 6).

Reclaim Solvent 💚

Reusing solvents is encouraged[7] at the DMT nexus.

Used solvent from the microwave paste process saturates with tan color and can be reused many times. This process is recommended for reuse. The non microwaved paste seems to load the solvent with chlorophyll indefinitely, making it black/opaque and difficult to reuse.

Wash spent extract with sodium carbonate saturated water (35% by weight). About 1/5 of the solvent volume as saturated water is enough. Shake vigorously (emulsions do not form). CO2 bubbles may be visible during citric acid neutralization. Neutralization can be optionally verified with pH paper. Filter any excess sodium carbonate/citrate and remove the water layer. Tan solvent can be reused on another microwaved paste.

Appendix: Development Notes 🔬

Paste 🌵

No improvements were seen with longer basing time, drying, or increasing the ionic strength.

Paste made with sodium carbonate saturated water congeals over time and requires long solvent soaks which are darker and don't crystallize to large loose crystals (small sticky crystals were obtained).

In the optional microwave treatment, Microwave Assisted Saponification (MAS[8]) breaks down esters (generally soluble in ethyl acetate which is itself an ester) into carboxylate ions and organic alcohols. An important example is,

This breakdown reduces the total amount of plant matter in the extract. In general, large complex esters become smaller organic alcohols. The resulting extract has improved crystallization, but this step is not required to obtain a product.

Extract 👨🏾🔬

Tests with longer/warmer pulls resulted in darker extract, smaller crystals, solvent paste absorption, congealing of paste, and no yield benefit.

Chemically drying the extract with a drying agent such as anhydrous CaCl2 or MgSO4 had no benefits.

Crystalize ✨

During crystallization, every 233mg of citric acid (H3Cit) react with free base mescaline (Mes) to form to 1g of mescaline citrate (or slightly more if a hydrate is precipitating):

Excess citric acid shifts the precipitation reaction to the right (Le Chatelier's principle), helping overcome water and plant material. There is a lot room for excess citric acid in solution since its solubility is 50mg/g in ethyl acetate. The TEK has options ranging from ~6 to 18mg/g and since cacti and pull techniques can vary, users may find other values work better for their specific situation (in one example with whole cactus powder 20mg/g was used [9]).

Several factors can make crystals smaller: Reusing ethyl acetate, longer/warmer pulls, higher citric acid concentration, mechanical agitation, and other potential variables. Small crystals can look like a fine powder. Potency does not seem affected by the crystallization appearance, and a powdery precipitate is not a problem unless it becomes difficult to decant/filter.

After the initial crystallization, adding more citric acid and/or moving the extract to the refrigerator did not result in any more precipitation. Moving the extract to the freezer produced ice crystals.

Other dry organic acids could work. Malic was tested but did not work as well as citric[10]. Fumaric, Tartaric, Ascorbic, Succinic, etc can be tested in future investigations.

10% sulfuric acid was tested and while some crystals formed, a separate liquid layer also appeared making the process not practical.

Collect 💖

Washing crystals in a filter appears to wick away plant colors and superior to decanting.

The washed crystals in the filter can also be dissolved in warm water along with any wall crystals. This will give then final product a uniform appearence.