CIELO

Contents

Introduction

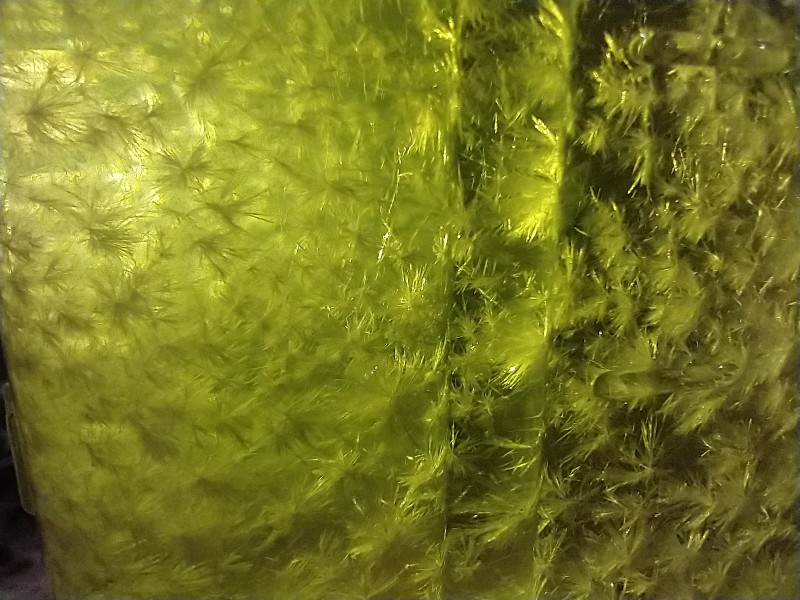

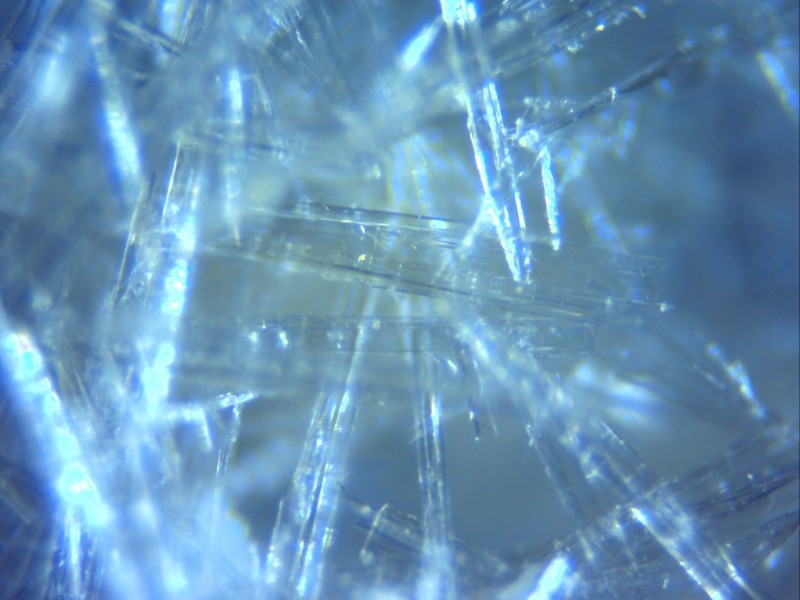

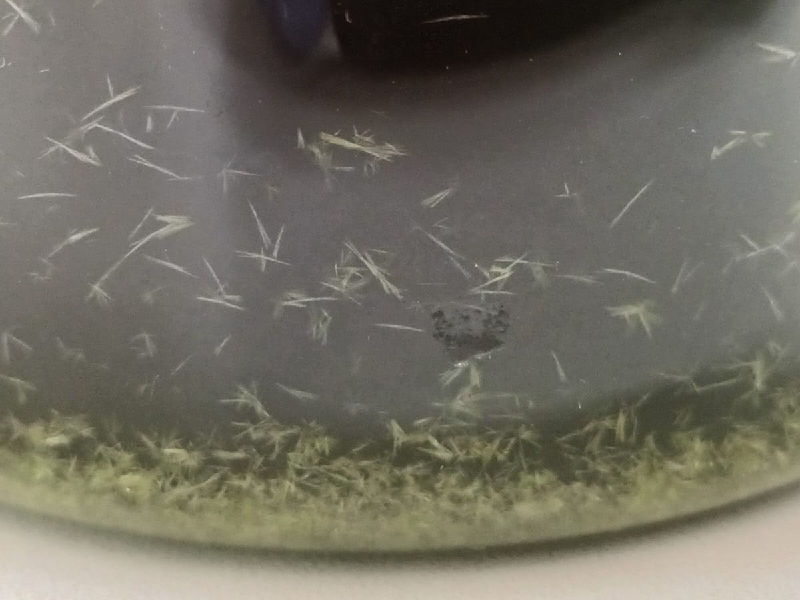

CIELO stands for Crystals In Ethyl-acetate Lazily Over-the-counter. In this process, mescaline from cactus is precipitated in ethyl acetate as crystals (see Fig. 1). This technique (TEK) is specialized for cactus, simple, and avoids harsh chemicals. The process needs to be followed closely to ensure good results.

Please grow your own cacti [1], [2]. Echinopsis cacti containing mescaline are being over-harvested in the wild in a non sustainable way [3], [4]. You can ask in the Nexus forum how to obtain live seeds. With patience and love, we can all extract the essence of the plant sustainably 🌵💚

This process was developed in a collaborative open source effort at the DMT nexus website[5]. No parts of this procedure may be patented or used for profit. The information presented here and any modifications to it may be distributed freely with a reference to this source and with love.

Thanks to everyone who contributed to this process: someblackguy, benzyme, shroombee, Metta-Morpheus, downwardsfromzero, Kash, grollum, Mindlusion, Doubledog, Dreamer042, merkin, _Trip_, Cheelin, Highlightprotein, Loveall, orchidist, BlackRose, endlessness, Madhattress, and others.

Safety ⛑️

Review ethyl acetate[6] and citric acid[7] safety information. Verify solvent MSDS, plastic compatibility, and clean evaporation.

This TEK is food safe if food grade materials are used. Use food grade citric acid since some of it will be in the final product as mescaline citrate.

Following this advice does not guarantee safety. It is up to each adult individual to make their own personal decisions.

Materials🛒

Consumables👩🌾

- 100g dry fine cactus powder

- 130g water + another 130g water as reserve

- 25g Ca(OH)2 (lime)

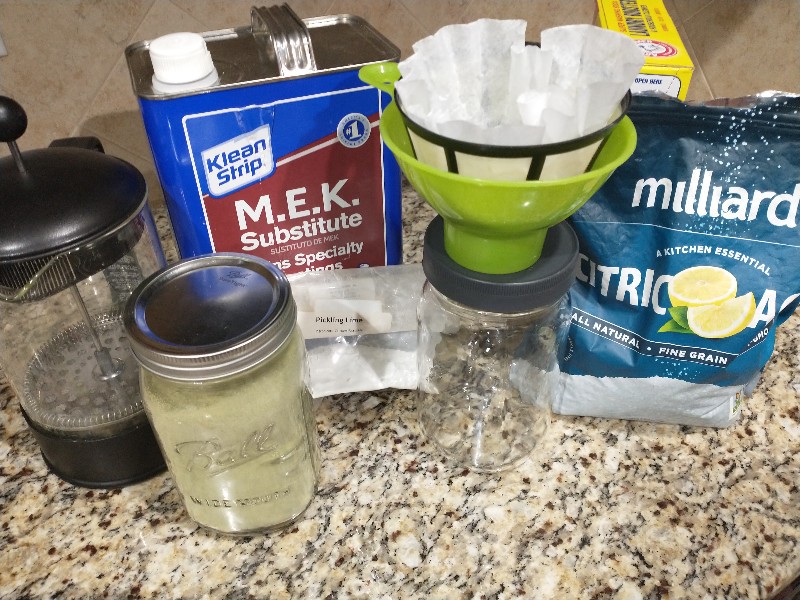

- 1L to 2L (1qt to 2qt) ethyl acetate (sometimes sold as "MEK substitute")†

- 5g (~ 1tsp) of food grade citric acid (both anhydrous or monohydrate are suitable)

- Optional: 15g (~1 Tsp) of washing soda (anhydrous Na2CO3 sold as arm and hammer super washing soda).

† while 1L (1qt) of ethyl acetate is usually enough to extract most of the mescaline, depending on pull technique using two quarts of ethyl acetate may yield a little more mescaline (up to ~+10%). See extraction section for more details.

Equipment🏺

- Knife, paper bag, dehydrator, food processor, and coffee grinder (to harvest plant, store cutting, and make cactus powder)

- Kitchen gram scale (to measure ingredients)

- Large bowl and spoon (to mix alkaline cactus paste)

- French press (all metal model 34 oz. or larger preferred)

- Coffee filters, filter basket, and funnel

- Quart or mason glass jars with lids (to collect and salt extract)

- Milligram scale (to measure product)

Reccomended Upgrades

- Stand mixer with flat beater

- Magnetic stirrer

Process Overview 👀

In short:🌵➠🟢➠🧑🏾🔬➠✨➠💖➠💚, where,

- 🌵: Grow, harvest, store, dry, and grind cactus

- 🟢: Mix powder into minimally wet uniform lime paste

- 🧑🏾🔬: Pull paste with ethyl acetate

- ✨: Precipitate mescaline with citric acid

- 💖: Collect monomescaline citrate crystals

- 💚: Reclaim ethyl acetate for reuse

Detailed Process 📜

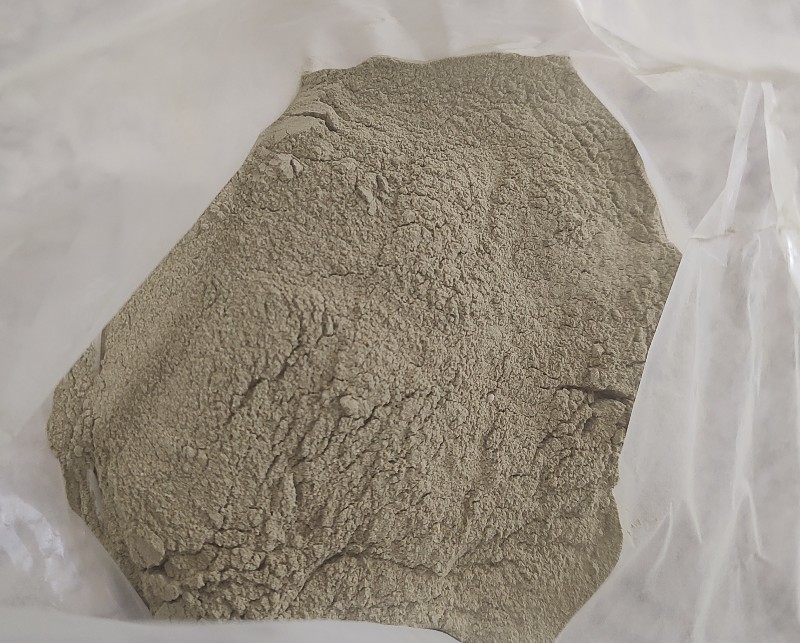

Powder 🌵

Grow [1], [2] and harvest cactus. Store cuttings in a dark place for at least 3 months (e.g. in a paper bag or wrapped in newspaper). Data shows dark storage increases mescaline content[8], and that the top part of the plant contains more mescaline[9]. Chop whole cacti (into for example ~1/4 inch thick slices) and dry them with (for example) a food dehydrator at low temp (~115 F). All parts of the cactus can be used. Outer green skin yields more than the inner white core for the same dry mass[10], but mescaline is present in both parts of the plant. Outer waxy layers and spines do not yield product, they can optionally be removed but that is not necessary because they are not detrimental to the extraction. Grind dry cactus slices to a fine powder. This can be done in two steps, first through a food processor (coarse grind) and then through a coffee grinder (fine grind). Use of grain mill is also reccomended. See Fig. 2a for representative images going from seed to powder.

It is very important to make a uniform cactus powder that is dry and finely ground. The fine grind enables good yields. Clouds of fine dust fly into the air when handling a good powder, reminiscent of flour (but green). Store properly sealed to avoid moisture absorption over time. Old cactus powder may change to a tan color, and still works well in this process, however extract may be tan and that color may make it to the product. No differences in subjective effects have been noticed for different off-white product colors (green/yellow/tan).

Paste 🟢

Proper paste consistency is extremely important. Take your time with this step and focus on it. Mixing can be done with a spoon and a lot of elbow grease. Alternatively, a stand mixer with a flat beater will make mixing very easy and is a great upgrade.

Mix the finely ground cactus powder and lime together until uniform. Add ~130ml of water, mix well for at least 5 minutes, and check consistency.

Typically, a "wet crumb" consistency is reached (Fig. 3 top left). Slowly add water while mixing right until the crumbs blend together into a uniform consistency (Fig. 3 top right). Goal is to use minimal water to get a uniform crumb-free paste. Mix well for a few minutes before adding more water; it can take some time for the water to incorporate and reveal the true paste consistency.

If by mistake the paste becomes too wet, adding more cactus powder and lime will make it dryer.

Extract 🧑🏾🔬

Transfer the paste to a french press. Cover paste with ethyl acetate (~200g) and stir for three minutes (see Fig. 4)*. Pour extract into a clean quart jar trough a coffe filter. Squeeze the french press to recover as much ethyl acetate as possible while watching for water droplets (if any are seen the paste was too wet and squeezing should be stopped).

* Room temperature ethyl acetate works and gives good results. Another option is to use fridge temperature (~40°F or 4.4°C) ethyl acetate. It has been found to also work and give matched yields with some advantages: (1) less smell, (2) less water absorbed, (3) more time to complete pulls, and (4) lighter saturation color.

Repeat the extraction with ~150g of ethyl acetate until the extraction jar is full (5-6 total pulls). The paste consistency will become more sticky as the pulls progress. A small yield boost can be done by optionally doing more pulls into a second jar. This second jar is also a good check on the effectiveness of the pulls in the main jar the first time this TEK is performed. Poor execution (sloppy technique, cactus powder not ground fine enough, paste too wet, etc) will give a larger yield boost in the second jar. A <10% boost in the second jar is considered good[11]. An additional check to verify the paste is spent can be done by leaving 200g of ethyl acetate in the french press for 3 days so the congealed paste can be extracted by diffusion. Less than 3% additional product from this step is considered a successful pulling technique in the main process.

All of the extraction pulls should be completed within 45 minutes (see Fig. 4b). After 45 minutes the paste can begin to congeal, making solvent penetration and recovery more difficult. There is plenty of time to lazily perform the pulls by remaining focused on the task. However, extracting in a warm environment may shorten this time. Hours after the last standard pull, the congealed paste will have released a few ml of solvent which can be optionally added to the extraction.

The spent paste can be dumped in a compost pile outdoors when not raining. Residual trapped ethyl acetate (~100ml) will quickly evaporate and the lime amend the soil. Alternatively, allow the paste to dry in a ventilated area and dispose of it in the trash.

Partial Dry (Required for begginers)

This step can be skipped if the paste was ideal. However, achieving an ideal paste requires practice and skill. Beginers may have too much water in their paste, which makes it into the extract and can interfere with xtalization, causing goo.

To ensure water levels are correct, add a tablespoon of washing soda to the extract, shake for a few minutes, and rest overnight in the fridge. The washing soda will absorb some water and partially clump* ♡. Filter the extract and proceed to the next step.

*If all the washing soda clumps up or a water layer forms, the extract (and paste) is too wet. You are at a risk of goo. Isolate the extract and repeat the partial dry until some washing soda does not clump. Improve your paste technique (fine grind, mix well adding water slowly giving it time to fully incorporate, etc).

♡If none of the washing soda clumps, congrats! This is an indication that your extract was not excessively wet and you made an ideal paste. Next time, you can try to salt your extract without a partial dry. It is reccomended to do a small test run with 10% of the extract to verify xtals form without the need for a partial dry.

Crystallize ✨

Drop ~5 grams (~1 teaspoon) of citric acid into extract. Do not under salt with citric acid since it is necessary to have excess citric acid to form crystalline momomescaline citrate (gooey trimescaline citrate can form in alkaline conditions). Allow the citric acid to dissolve by diffusion without stirring. Extract will cloud as the dissolved citric acid reacts with mescaline freebase to form insoluble mono-mescaline citrate. Cloudiness may be hard to see in darker extracts (a backlight may help). If the citric acid is anhydrous and/or coarse it may take a while to dissolve, however it WILL dissolve fully. Leave cloudy extract undisturbed and sealed with a lid. Crystals of monomescaline citrate should begin to appear after a few hours, and take a few days to completely crash out (at least 3 days of wait is recommended).

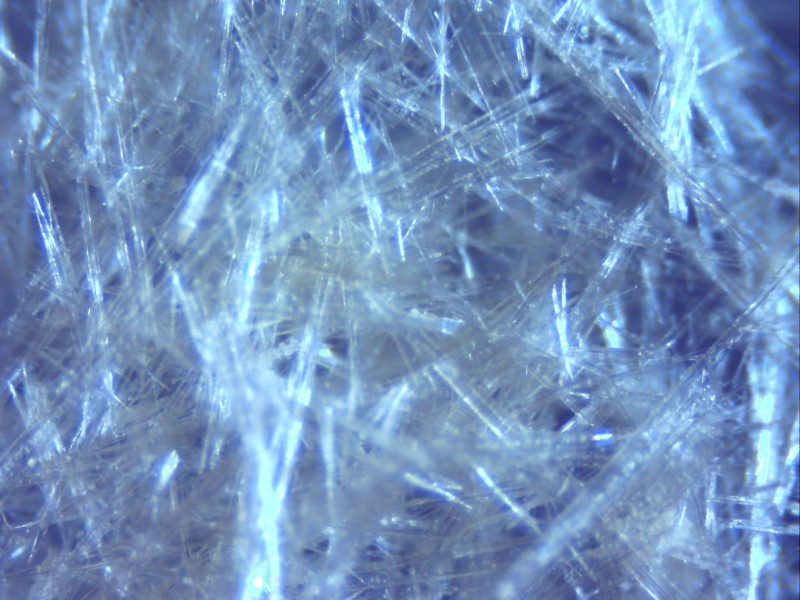

Crystals can have different shapes and crystallization dynamics. In general, more agitation/stirring/lifting jar to check makes smaller/powdery crystals while dissolving by diffusion and rest produces larger needles. See appendix for other crystallization options.

If no crystals form and goo appears, see FAQ below. If goo still results after taking the FAQ suggestions into account, please report this on the DMT nexus.

Collect 💖

Swirl ethyl acetate to knock crystals loose. Crystals that cling to the wall can sometimes be dislodged by shaking or with a knife/spoon. Send solvent through a coffee filter to catch crystals (note: do not store the used solvent in a metal can because excess citric acid can corrode metal). Rinse any crystals remaining on jar walls with fresh ethyl acetate and send wash through filter to wash the crystals there and collect any loose crystals remaining in the jar (repeat ~2-3x until off color is mostly removed).

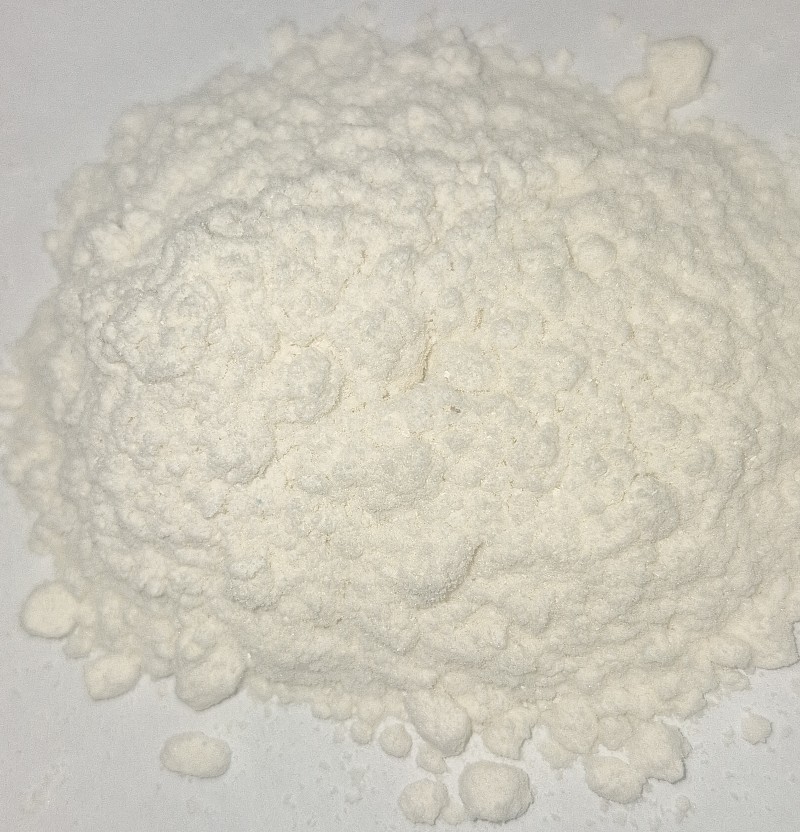

After the solvent washes are dry collect crystals in the filter by sliding them off. Rubbing the inside of the filter against itself with the palms of the hands can help loosen the last bit of crystals. This is the final product (Fig. 6).

Yield depends on the cactus and is usually between 0.3% to 3% with ~1.2% being common[12]. However, yields up to 8.2%[13] (5.0% mescaline HCl equivalent) have been reported.

The product is monomescaline citrate with 1.5 molecules of water per molecule of salt (see fig 6a). This hydrated salt contains 491mg/g of mescaline which was verified separately by Altitude Consulting measuring 492mg/g of mescaline

(anonymous source). The rest of the hydrated salt is 447mg/g citric acid 63mg/g of water. The product is therefore ~58% as strong as Mescaline HCl which contains 853mg/g mescaline.

Attempting to smoke the product is not recommended as potentially unwanted compounds can form [14], [15].

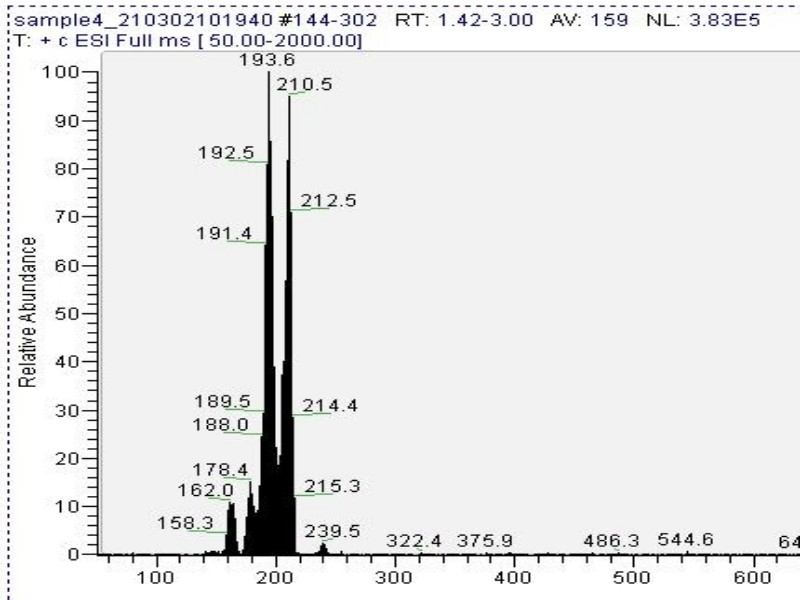

Mass spectrometry (MS) results from Solaris analytical[16] indicate the product is very clean mescaline (Fig. 7a) in one example where pachanoi was used. It is unknown if cacti with different starting starting alkaloid profiles would give the same result, and more data is needed to make that claim.

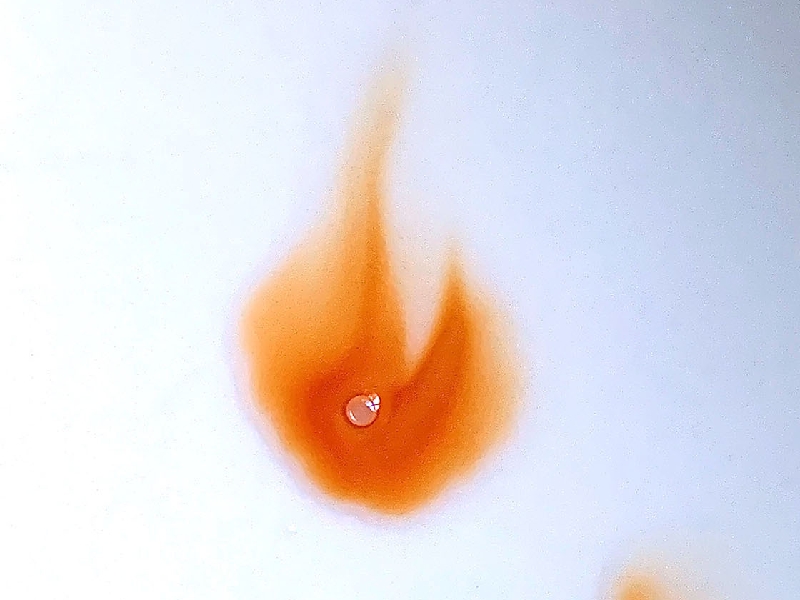

Testing the product with marquis reagent gives a bright orange color as expected[17] (see Fig. 7b). Several reagent results for the product from this TEK have been published by _Trip_[18].

Tip: The coffee filter used to collect the crystals can be re-used upside-down before salting. Any small crystals not collected may be forced into the extract and subsequently act as seed crystals for the next extraction[19].

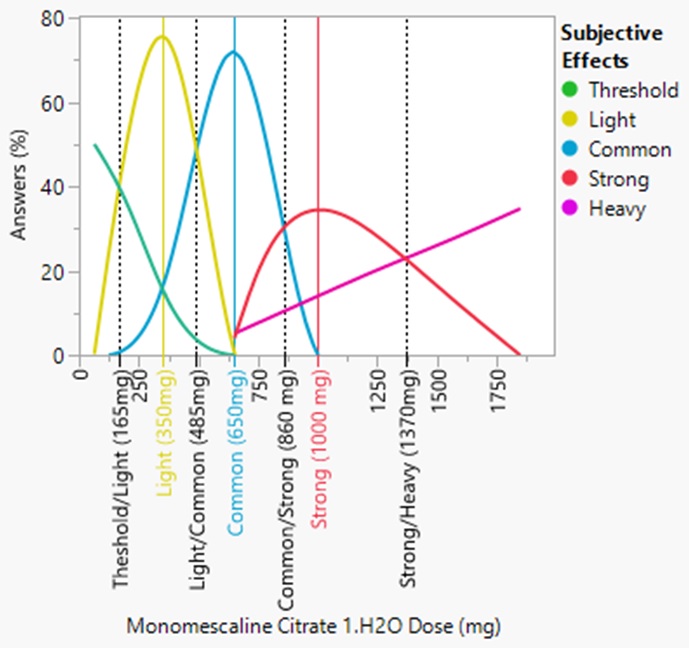

Dosage ⚕️

The mescaline experience is subjective. It can vary by individual and can be affected by the environment. Natural settings usually go well with the mescaline experience. A small group of trusted loved ones or close friends also goes well with the experience. When deciding on a dose for a desired experience classification[20], the results of several non-scientific poll results indicate the following (see Fig 7c):

- Threshold: 100 - 165 mg

- Light: 165 - 485 mg, typically 350mg

- Common: 485 - 860 mg, typically 650mg

- Strong: 860 - 1370 mg, typically 1000mg

- Heavy: >1370mg

Reuse 💚

Reusing solvents is simple, environmentally friendly, economical, and highly encouraged[21] at the DMT nexus.

To reuse, the excess citric acid will be removed. The green chlorophyll does not interfere with the process and will remain. There is no limit to the number of reuses.

Before washing solvent, check for new crystal grown and collect any new product if present. Sometimes, a small amount of product precipitates after the main collection.

It is not necesary to remove the green/dark color present in the solvent because it does not affect the TEK and remains stable after many reuses (chlorophyll saturation).a Also, any mescaline that does not crystallize in the main extraction will mostly remain in the ethyl acetate during regeneration.

Do not store salted solvent in metal cans. The excess citric acid can make them rust. It is ok to store neutralized/washed solvent back in the original metal can.

There are two options to regenerate the solvent. The option that uses a magnetic stirrer is a lot less work and is reccomended.

With Magnetic Stirrer

For each teaspoon of citric acid used during salting, add a teaspoon of sodium carbonate and a teaspoon of water to the solvent, cover loosely, and magnetically stir for 12 hours.

CO2 bubbles from the neutralization reaction will begin to appear after a few minutes (best seen by shining a light). If they don't appear, add an extra teaspoon of sodium carbonate and water to speed up the reaction. Neutralization reaction is complete when bubbles stop, and can be verified with a pH paper.

A cloudy haze of sodium citrate from the neutralization reactiom will appear over time (best seen by shining a light). If the solvent has enough water, hydrated sodium citrate subsequently forms and drops out of solution as a wet white solid layer. If cloudiness persists after 12 hours, add a tablespoon of water and check again after another 12 hours. Repeat until cloudiness dissapears.

Finally, stop the magnetic stirrer, rest the solvent for a few minutes, and pour off the neutralized clear extract from the wet clumped up solids (sodium carbonate and sodium citrate) through a coffe filter. The solvent is reclaimed and ready to use.

Note: if the xtalization during the main TEK did not completely finish (impatience, mistake, etc), the reclaimed solvent will carry any residual mescaline to the next extraction.

Without Magnetic Stirrer

Are you sure you don't want a magnetic stirrer? Regeneration of one quart of solvent is done in two steps:

1) Add a tablespoon of sodium carbonate and 50ml of water to the extract. Shake vigorously, releasing CO2 gas as citric acid reacts with sodium carbonate. Neutralization can be verified with pH paper and/or the absence of pressure buildup. If excess citric acid is used (above the TEK's main recommendation) more sodium carbonate may be needed for neutralization (0.83 parts sodium carbonate neutralize 1 part citric acid). It is important to remove all the citric acid and it can take 5 minutes or more of shaking to fully neutralize the extract. A water layer may form above the excess sodium carbonate and the extract will cloud. Afer resting for at least an hour, decant neutralized extraxt into new jar (you may need to leave a small ammount of solvent behind when decanting: it can be added to the next extraction's neutralization). Optionally, use a separatory funnel to recover all of the neutralized extract.

2) Wash neutralized solvent with a tablespoon of salt and ~50ml of water. The solvent cloudiness will change after shaking for a few minutes. Rest the solvent in the fridge for a few hours until a backlight shines through clearly. Decant into a long term storage container (e.g. original solvent can if empty). As before, you will need to leave some solvent behind wich can be added to the next brine wash). Optionally, use a separatory funnel to recover all of the washed extract.

Frequently Asked Questions ❓

Q: I froze my cuttings, is ok to proceed with the TEK?

A: No. Freezing the cuttings will change the consistency of the paste during the pull, resulting in a pancake-like batter mixture and low yield [22]. If you proceed anyway and find a way to make it work (less water, more lime, etc) please share with your result with the community on the dmt nexus.

Q: I bought cactus powder only and I'm getting a low yield, is this normal?

A: Yes. Online powders typically yield below 1%, with 0.5% being common. Buying powders online is not recommended as it can finance poaching and plant destruction in the natural habitat. Instead, grow your own cacti if possible. If not possible, go out there and make it possible. Finally, be warmed that mescaline is a gateway drug to gardening.

Q: Does increasing the basing time increase the yield?

A: No. Shroombee has tested 15 minute, 24 hour, and 72 hour basing times and there was no difference in yield. Other process variables were 8 minutes incorporating milky water with cactus, 6x3 minute pulls, and 15 mg/gram citric acid added with the fast crystallization method. Loveall has confirmed in his experiments that 10 minute and 24 hour basing times produce the same yield. So we assume that any basing time from 10 minutes through 72 hours will produce the same yield. See a detailed explanation in this post.[23]

Q: I got an emulsion while pulling, what do I do?

A:If the paste and solvent form an emulsion, the paste was too watery. Add lime and dry magnesium sulfate until the paste becomes chunky again and solvent is released. Keep the lime to magnesium sulfate ratio above 1 to ensure paste remains alkaline[24]. Next time, use less water to make the paste.

Q: I have a thick bottom layer in my pulling jar after the fridge rest. What is it and what do I do?

A: It is a water layer. This can happen if you squeeze the French press aggressively and/or the initial paste is too wet. Without these issues only a few ml of water crash because of the lower solubility of water in cold ethyl acetate. Luckily, the TEK is robust to this issue. Simply separate the layers using a pipette or separators funnel and continue the TEK with the top ethyl acetate layer. The water layer should be pulled with ethyl acetate since some mescaline was likely partitioned into the large volume of water (for the standard small volume of water an extra pull is not needed). The TEK can be continued with these pulls at the fridge rest step.

Q: I heard of people using more citric acid and shaking. What’s the difference between the two crystallization methods?

A: In general, adding more citric acid and aggressively stirring or shaking will:

- Force crystals to form faster

- Form smaller and denser crystals (can be powdery in appearance) less likely to stick to the jar walls

- Cause a negligible amount of tiny crystals to drop through the coffee filter.

Q: What is the upper limit of citric acid that can be added to the extract?

A: The solubility of citric acid monohydrate in ethyl acetate is over 50 mg per gram of ethyl acetate[25]. Note that plant matter or other unwanted extraction products (such as water) may affect the solubility. Stay well under 50 mg/gram limit and do not chemically dry the extract to ensure no undissolved citric acid is mixed in with the mescaline citrate. Under mostly anhydrous conditions the solubility of anhydrous citric acid in ethyl acetate has been measured as low as 10mg/g [26].

Q: After adding citric acid, I saw clouds followed by precipitation, but the precipitate reminds me of citric acid. How do I know a mescaline salt is precipitating and not citric acid?

A: Citric acid does not precipitate and stays in solution because it is well bellow its solubility limit (50mg/g) in the TEK. The white particles that form from the clouds after citric acid has dissolved are mescaline salts and not citric acid.

Q: After adding citric acid, nothing precipitated, what gives?

A: Check the jar walls, a transparent product may have precipitated there (e.g. this has been reported for whole bridgesii[27]). If product bid not present on walls as a transparent film, bring up the citric acid concentration up to 20mg/g or more (stay below 40mg/g due to solubility concerns) and wait a few days. Keep in mind that if your cactus is not active, no mescaline citrate will form. If all else fails, pulling the salted extract with water, evaporating, and washing citric acid with fresh ethyl acetate should leave behind a residue containing any mescaline in the cactus (dose will be less accurate and can be made proportional to starting cactus amount). The crystallization temperature should not be colder than the previous extraction settling temperature. Water layer formation is sensitive to temperature, and lower temperatures can produce a new water layer.

Q: After adding citric acid, goo/oil precipitated instead of crystals, what gives?

This is the most common issue people encounter. In one example from Cheelin the goo was 65% mescaline citrate[28]. In another example, goo was measured to be roughly equal parts water, citric acid, and mescaline citrate [29]. The cause is usually an issue with the citric/water/mescaline ratio when salting. Most people report that too much water was their issue, but too little citric acid or not enough water can aslo cause problems. An issue with ratios can be avoided with good starting materials and good TEK execution:

- Ensure you are using an active cactus (>0.4% mescaline). Low mescaline concentrations can fall outside the proper cyrstalization process window. People may encounter this when using low potentcy PC plants (note that not all PC plants are low potency for unkowm reasons).

- Good consistency paste (not too wet)

- Not excessively squeezing the French press

- If the paste is on the wetter side, need to rest extract in a cold fridge (at least 15C below extraction temperature) for the full 24h

- Careful decant of extract leaving all water droplets behind. A small amount of "sacrificial" solvent can be left behind to help keep the water away, this will not impact yield significantly. These dregs with a small amount of mescaline can be used in the next extraction if desired.

Before salting it is important to ensure water and debris are not present. Tilting the extract and shining a flashlight are needed for a good check. Take your time, especially the first time you try the TEK.

To reduce the water percentage, Shroombee suggests to add fresh ethyl acetate (usually relatively dry from the manufacturer) to the extract [30]. This can increase robustness if any water is missed by a novice. For example, by adding ~100g of fresh ethyl acetate to a quart of extract.

Some people recommend a freezer rest followed by filtering off the ice crystals that form. This is very effective at removing water without decanting skills. However, if a lot of water is removed with this technique, about 1 to 2% water needs to be added back before salting for good crystallization dynamics. This is a sledgehammer for water removal, and may be useful for those who don't trust their decanting skills or have fridge/ambient temperature issues (e.g. fridge is set to warm and/or crystallization environment is set too cold).

If you continue to encounter goo even after taking all this information into account, please report it on the forum.

Q: I recovered the goo/oil precipitate instead of crystals, what do I do?

A: A simple recrystalization with 99% IPA is recommended. Dissolve the goo in minimal heated 99% IPA (using a hot water bath). Move the IPA to the freezer where only mescaline citrate will precipitate. The product can be rinsed once with a small amount of freezer cold 99% IPA.

Q: How quickly can the extraction process be done?

A: With experience, and by skipping the fridge rest step (crystallization temperature should be warmer than extraction temperature, by for example using chilled ethyl acetate) it is possible to go from raw cactus powder to dry crystals in under an hour by choosing the fast crystallization method shaking the salted extract vigorously. Current documented world record is 48 minutes to go from cactus powder to dry mescaline crystals ready to use.[31]. However, there is an increased risk of obtain goo without the fridge rest step. The express process is not recommended for newcomers.

Q: The cactus paste turned to goo in ethyl acetate very quickly and I couldn't finish the timed pulls with a sandy consistency. How can I give myself more time?

A: Try using less water next time and keep resting powder time to 10 minutes. Excess water can accelerate 'goofication' of the cactus paste and decrease yield as it is harder to extract from goo due to poor solvent penetration. Not all cactus powder is the same, so a 'feel' is needed to achieve the right paste consistency before pulling. The initial water amount is only a starting guideline, the consistency is the goal and water amount should be adjusted as needed. Higher summer temperature pulls in the summer can also accelerate the paste to goo change.

Q: Why do I need to neutralize the extract before re-use?

A: Salted extract is acidic due to excess citric acid. The citric acid will react with the lime paste releasing small particles of calcium citrate into the extract, making a cloudy mess. While it is possible to rest/settle/decant these particles off with time, neutralizing the extract and washing it is reccomended by default.

However, if the operator would rather deal with calcium citrate as part of the extraction process, reclaiming the solvent is not needed. The resulting calcium citrate can be used as a supplement.

Q: Is there a lingo for this TEK

A: Yes, the clouds formed after salting are called "nubes" and the star shaped crystals growing on the jar walls as they clear "estrellas". These are the Spanish words for clouds and stars. You can practice your Spanish while doing this TEK. For example:

San Pedro vio nubes transformarse en estrellas en el cielo

Translates to

St. Peter saw clouds transform into stars in the sky

Appendix: Development Notes 🔬

Paste 🌵

No improvements were seen with longer basing time, paste oven drying, or increasing the ionic strength with CaCl2. Microwave treatment or boiling water resulted in a small yield loss.

Paste made with sodium carbonate saturated water congeals over time and requires long solvent soaks which are darker and don't crystallize to large loose crystals (small sticky crystals were obtained).

Use of lime and boiling water causes the saponification of chlorophyll over time [32]:

Chlorophyll is soluble in Ethyl Acetate, but Chlorophyllin and Phytol are not[33]. Saponification in hot water gives an extract with less plant matter and lighter color, however yields where slightly lower with this approach.

Extract 👨🏾🔬

Tests with longer/warmer pulls resulted in darker extract, smaller crystals, solvent paste absorption, congealing of paste, and no yield benefit.

Chemically drying the extract with anhydrous CaCl2 had no benefits, while drying with MgSO4 was problematic. However, depending on the worker and techniques used, a chemical dry with CaCl2 pellets (available commercially as de-icer) could reduce water content in the solvent and possibly make crystallization easier. Washing soda (when sold as Na2CO3 in monohydrate form, or when making the anhydrous form from baking soda with an oven) may also dry the extract and be beneficial in such cases (but that is currently an assumption based on other lab techniques).

Crystallize ✨

Alternative crystallization options:

- Shaken not Stirrer: Also called the 007 process. After adding the citric acid, shake the sealed jar vigorously. The citric acid will dissolve quickly and small crystals will recipitate as the shaking continues. After 15 minutes, shaking will crystallize most (but not necessarily all) of the product out of solution quickly.

- Fast crystallization option: Use a magnetic stirrer to dissolve the citric acid and speed up crystallization. This produces a fast crystallization and minimizes crystals that are stuck to the wall. A stirring vortex will go from visible, to not visible as clouds form, to visible again as mescaline citrate precipitates (see Vid. 1). Crystallization is comolete within two hours. Crystals will be very small with this approach and look like a powder. The crystals should still be large enough to be caught by a filter, but if some are not caught, slowing down the magnetic stirrer will produce larger granules in subsequent runs. The resulting powder is are dense and easier to pack in capsules compared to the long needles, but not as pretty to look at (see Fig. 8aa).

- CASEA: Endlessness has reported success with this method. In his words[34]:

I added 11.1g anhydrous citric acid in 250ml ethyl acetate. It did not dissolve much at all, even after overnight stirring in a magnetic stirrer and some time in the ultrasonic bath.So I decided to add water in small amounts until it all dissolved. It took about 5ml water for the citric acid to dissolve completely.

So I added all the 250ml CASEA, and there was immediate clouding. After 1 hr it looked like this (see Fig. 8a):

During crystallization, excess citric acid (H3Cit) reacts with free base mescaline (Mes) to form to form the monomescaline citrate salt (MesH)H2Cit, which preliminary NMR results indicate could be a hydrate:

Monomescaline citrate salt's strength relative to mescaline HCl is 61% (assuming no hydrate formation)[35]. By not using excess citric acid, different salt forms can be precipitated[36], but that process is more complex than the simpler excess citric acid approach.

There is a lot room for excess citric acid in solution since its solubility is 50mg/g in ethyl acetate. In extracts with crystallization issues, adding more citric acid can help force precipitation: in one example with whole cactus powder 20mg/g was used [37].

Several factors can make crystals smaller: Reusing ethyl acetate, longer/warmer pulls, higher citric acid concentration, mechanical agitation, and other potential variables. Small crystals can look like a fine powder. Potency does not seem affected by the crystallization appearance, and a powdery precipitate is not a problem unless it becomes difficult to decant/filter.

After the initial crystallization, adding more citric acid and/or moving the extract to the refrigerator does not result in any more precipitation. Moving the extract to the freezer produced ice crystals.

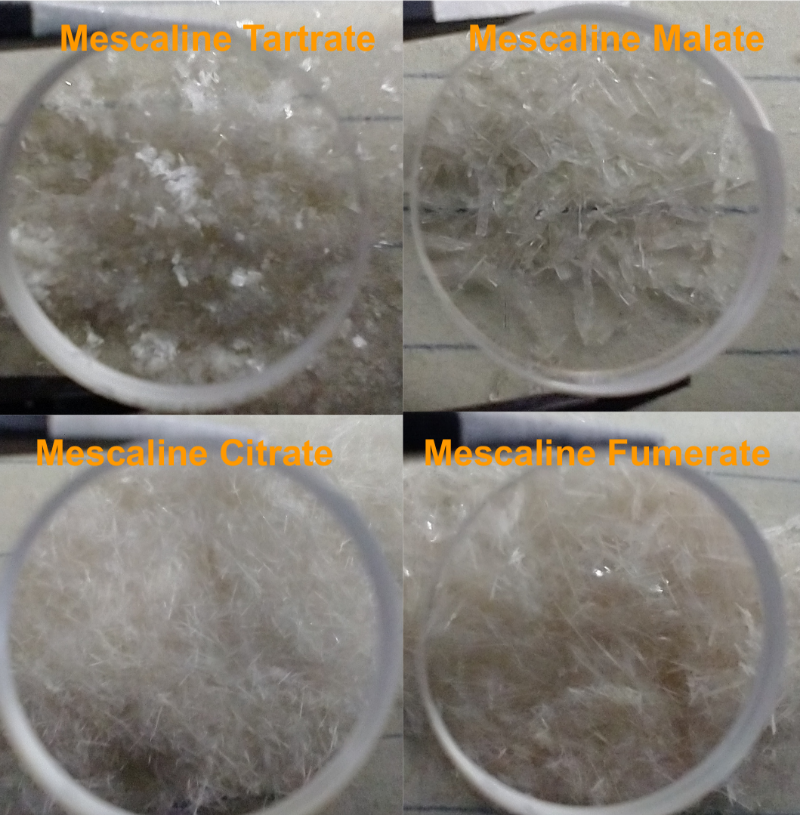

Other dry organic acids have been tested[38],[39]. Fumaric and tartaric crystallized well as monomescaline and could be a substitute for citric. Malic also crystallized but took longer to do so, and a crude mass measurement indicated the dimescaline form. See Fig. 8b for resulting citrate, tartrate, fumarate, and malate crystals. Succinic also crystallized from a chemically dried extract (without drying crystals did not form[40]) as the monomescaline form (see Fig. 8c). Ascorbic, and benzoic did not crystalize well. Other organic acids (lactic, oxalic, etc) have not been tested yet at the time of this writing. For the organic acids that crystallized, Mescaline HCl equivalent is (assuming no hydrate formation):

- Monomescaline Citrate: 61%

- Monomescaline Tartrate: 69%

- Monomescaline Fumarate or Succinate: 75%

- Dimescaline Malate: 89%

For a comprehensive reference of mescaline salt weight conversion see orchidist's calculator[41].

10% sulfuric acid was tested and while some crystals formed, a separate liquid layer also appeared making the process not practical. HCl has not been tested as it may break down ethyl acetate.

Collect 💖

Washing crystals in the filter with a splash of fresh ethyl acetate wicks away plant colors very effectively. It is the ultimate lazy purification method.

Any product sruck to the jar walls tends to be small. If a lot of it sticks to the wall, the inital paste could be too wet. The lazyest way to collect this small ammount of product is to dissolve it in water used in the next extraction.

Reuse 💚

Dark extract can be cleared up with activated carbon (also called activated charcoal). Use dustless pellets (typically rinsed with water and dried before use).

Any benefit to using activated charcoal to decolor the used solvent is not clear (pun intended). Alsi, the environmental benefit of regenerating a colorless solvent is in question since ethyl acetate is easy to produce and activated charcoal requires resources to manufacture. However, if the activated charcoal itself can be regenerared (e.g. in a hot oven) it may ne economical to use it if a colorless solvent is wanted. However, there is no benefit to this other than esthetics since the final product is same regardles of the color of the starting solvent (provided some fresh ethyl acetate is available for the rinse).

References 🗝️

- ↑ 1.0 1.1 Sowing Cactus Seeds[1]

- ↑ 2.0 2.1 Cactus growing guide (PDF)[2]

- ↑ Huachuma Collective Talk[3]

- ↑ Huachuma Collective statement (PDF)[4]

- ↑ DMT nexus website[5]

- ↑ Ethyl acetate safety[6]

- ↑ Citric Acid Safety[7]

- ↑ Dark storage data[8]

- ↑ Paper with vertical signal[9]

- ↑ Result for different cactus parts[10]

- ↑ Second set of pulls [11]

- ↑ Cactus analysis thread[12]

- ↑ High bridgesii yield[13]

- ↑ Citric acid heat degradation[14]

- ↑ Direct heat vaporization test[15]

- ↑ Solaris analytical service[16]

- ↑ Marquis reagent result[17]

- ↑ Reagent results[18]

- ↑ Filter reuse[19]

- ↑ Experience Classification[20]

- ↑ On reusing non polar solvent[21]

- ↑ Freezing cutting result[22]

- ↑ Basing time tests results[23]

- ↑ Lime and magnesium sulfate ratio vs pH[24]

- ↑ Citric acid solubility[25]

- ↑ Anhydrous citric acid solubility test[26]

- ↑ Whole bridgesii precipitate on jar walls [27]

- ↑ Goo conversion to crystals[28]

- ↑ Goo measurements[29]

- ↑ Fresh ethyl acetate to lower water content before salting[30]

- ↑ Plant to crystal record [31]

- ↑ Hot water saponification with lime[32]

- ↑ Phytol not present in Ethyl Acetate plant extract[33]

- ↑ Endlessness' CASEA[34]

- ↑ Mescaline citrate vs HCl[35]

- ↑ Trimescaline citrate candidate[36]

- ↑ Ethyl acetate approach[37]

- ↑ Organic acid tests[38]

- ↑ Succinic test[39]

- ↑ Wet solvent succinic salting[40]

- ↑ Orchidist's mescaline salt calculator[41]