Difference between revisions of "Chilled Acetone with IPA and Naphtha"

(→Reclaim Solvent 💚) |

(→Safety ⛑️) |

||

| Line 13: | Line 13: | ||

= Safety ⛑️= | = Safety ⛑️= | ||

| − | Review | + | Review NaOH<ref>Ethyl acetate safety[https://www.msdsonline.com/2015/04/10/ethyl-acetate-a-sweet-smelling-safety-hazard/#:~:text=Ethyl%20acetate%20is%20highly%20flammable,with%20the%20eyes%20or%20skin.]</ref> and naphtha <ref>Citric Acid Safety[https://wiki.dmt-nexus.me/Citric_Acid_Safety#Process_.F0.9F.A5.9E]</ref> safety information. Verify solvent MSDS purity, plastic compatibility, and clean evaporation. |

Never have solvents near an open flame. | Never have solvents near an open flame. | ||

| − | |||

| − | |||

| − | |||

Revision as of 12:58, 19 October 2021

Contents

Headline text

Introduction 🙏

Min Poly stands for Minimun Polymer.

In this technique (TEK), DMT polymers (also called DMT aggregates or DMT oligomers) are minimized. First, any natural DMT aggregates are broken down in an acidic pressure cooking process using vitamin C. Secondly, during the basing step, ionic strength, alkalinity, and DMT concentration are kept low to avoid DMT (re)polymerization.

Thanks to Dragonrider for sharing his excellent pressure cooking experimental result, to Benzyme for showing MS evidence of DMT aggregates, and to Jees, Downwardsfromzero and Loveall for their contributions to this process.

Safety ⛑️

Review NaOH[1] and naphtha [2] safety information. Verify solvent MSDS purity, plastic compatibility, and clean evaporation.

Never have solvents near an open flame.

Following this advice does not guarantee safety. It is up to each adult individual to make their own decision.

Materials🛒

Consumables👩🌾

- 200g water

- 20g washing soda

- 100g ground rue seeds

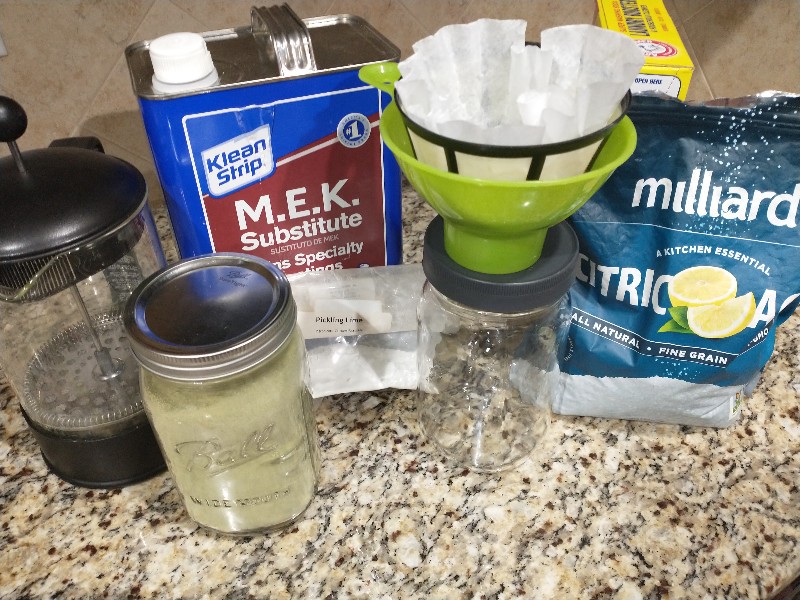

- ~3/4 qt ethyl acetate (also sold as "MEK substitute")

- 150ml of vinegar

- 30g of NaCl

- Additional washing soda and pH paper (to wash solvent for reuse)

Equipment🏺

- Coffee grinder

- French press for mixing and pulling rue with ethyl acetate (a quart jar also works but is not as easy as the French press)

- Microwave

- Quart jar to collect pulls and precipitate harmala HCl

- Coffee filters, support basket, and funnel

- Kitchen scale to weigh materials

- Pot and source of heat to warm water

Process Overview 👀

- Make wet alkaline microwaved rue paste

- Pull with ethyl acetate

- Salt with vinegar/NaCl solution

- Rest in fridge overnight for harmala HCl xtals to form

- Collect xtals, wash, and squeeze dry

Detailed Process 📜

Paste 🌵

Dissolve 20g of washing soda in 200g of water in a french press (or a quart jar). Ground rue seeds and add then to the alkaline solution a, stirring thoroughly. Microwave in short runs of 2-3 minutes stirring between runs until the paste has no running water (~100g of water removed).

Extract 👨🏾🔬

Cover paste with two fingers works of ethyl acetate (~100g) and stir for a few seconds. Loosely cover and heat in a hot water bath brining ethyl acetate to a boil (do not seal container to avoid pressure buildup). Extract with boiling EA for least 10 minutes, stirring every couple minutes or so (do not have any open flame sources and work in a well ventilated area). Decant into quart jar. Do not squeeze with the French press, its purpose is to only hold back the paste from falling into the filter. Squeezing can push unwanted plant material or water into the extract. Repeat adding ethyl acetate, heating, stirring, and decanting until quart jar is ~3/4 full. This will be about 5 total pulls.

Rest the combined extract for at least an hour and then inspect for droplets or particles. If present, allow extract to rest until no more debris form and remove them with a filter.

Room temperature extract option: With this option the paste is extracted at room temperature over 24 hours and shaken throughout the day. This extraction is more passive and slower, but yields are similar[7].

Crystalize ✨

Dissolve 30g of NaCl into 150 grams vinegar. Add this solution to the combined EA pulls. White clouds will form in ethyl acetate, shake to clear clouds and move harmala salts into the water layer. Rest for 10 minutes and if a red oil forms filter or decant it off. Move salted extract to the fridge for 24 hours. Harmine and harmaline HCl crystals should form in the aqueous layer.

Collect 💖

Catch loose crystals in a coffee filter. Rinse crystals on wall and filter with fresh ethyl acetate (~2-3x until off color is removed). Collect crystals stuck on the jar walls by dissolving them in warm water, evaporating in a shallow dish, and scraping up dry crystals. Combine with the collected crystals from the filter to obtain the final product (Fig. 5).

Yield depends on the cactus and is usually between 0.2% to 2% with ~1% being common[3]. The precise ratio of mescaline and citrate in the precipitate is not known and is under investigation (see development notes below). Preliminarily data indicate the salt made my this process is ~60% as strong as mescaline HCl and consistent with the salt form (MesH)H2Cit. Approximate oral dosage recommendations for mescaline HCl can be found elsewhere[4].

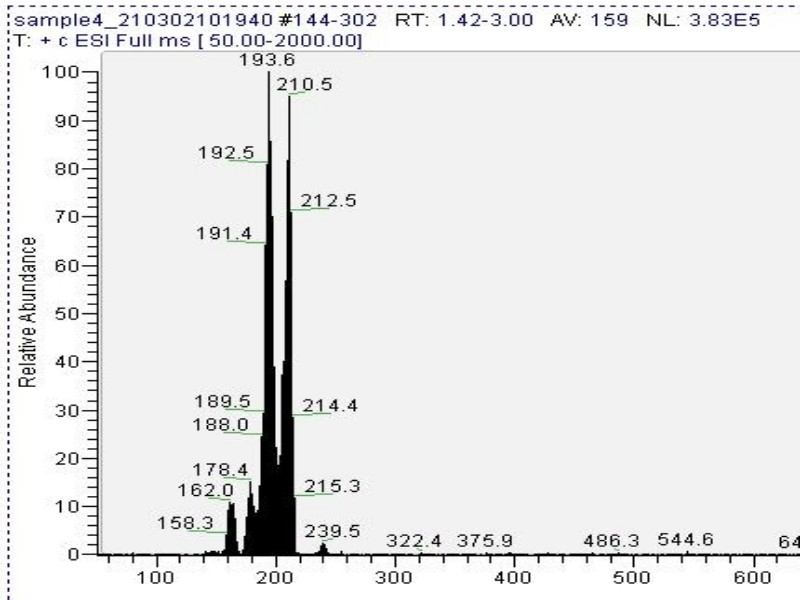

Mass spectrometry (MS) results from solaris analytical[5] indicate the product is very clean mescaline (Fig. 6).

Reclaim Solvent 💚

Reusing solvents is encouraged[6] at the DMT nexus.

Simply reuse freeze precipitated naphtha as-is. Re-used naphtha is saturated with DMT at freezer temperature and pre-freezer evaporation is not needed. Easy 😊

Frequently Asked Questions ❓

Q: That's a lot of hypothesis you got there. Have any experimental evidence consistent with them?

A: Yes. Benzyme's MS, along with more direct polymerization and de-polymerization experiments. As far as we know experiments are consistent with the hypotheses listed. The community is welcome to update this Wiki entry as more evidence arises, especially if any of the hypotheses are disproved (thank you).

Q: What's so special about citric acid?

A: See the development note below.

Appendix: Development Notes 🔬

Hypotheses 🤔

This technique (TEK) hypothesizes that:

- Not all of the DMT is in the plant in monometer form, some of it is in macro-molecule aggregates (sometimes called DMT polymers or DMT oligomers)

- DMT can also form aggregates during the basing step in high alkaline, high ionic strength, and high DMT concentration conditions

- DMT aggregates are more difficult to dissolve in naphtha compared to the DMT monomer and require heat. During freeze precipitation or evaporation from naphtha, DMT aggregates quickly cloud and precipitate as yellow/orange/red oils, while monomers cloud later and slowly form white crystals.

- DMT monomer benefits:

- Improved partition coefficient (fewer pulls for good yield)

- Easier to handle and dose precisely

- Low and consistent vaporization temperature, ideal for newer electronic vaporization devices with precisely tuned temperature settings

- Visibly unique upon crystalization, making confident identification easier

- Easier to complex with HPBCD for sublingual administration

- Other properties

- It is unknown if DMT monomer has better bioavailability for oral or rectal administration. In principle, stomach acid should be able to break down DMT into its monomer form

- There is no expected benefit for DMT monomer over DMT aggregates for torch vaporization

Strategy ♟️

The strategy of this TEK is to break down both DMT aggregates and plant material, while minimizing DMT re-aggregation during the basing step.

Agressive alkaline concentration conditions are avoided. While these type of processes can break down plant material, their downside is that they don't break down natural DMT aggregates and can even increase the degree of polymerization.

Fortunately, DMT aggregates can break down in acidic conditions. Therefore, to simultaneously break down DMT aggregates and plant material, a long acidic pressure cooking step is used (described before by for example Dragonrider). Vitamin C is chosen as the source of acid due to its good experimental performance, but other acids could also work. Subsequently, relatively gentle ionic strength (no added salt), alkaline pH (no excess lye beyond emulsion breakdown), and low DMT concentration (<0.5%) conditions are used to minimize any DMT re-aggregation. Naphtha is also present during the basing step to minimize the time DMT spends in the base when it is at its highest initial concentration.

Vitamin C 🍊

Experimentally, Vitamin C produced better results compared to acetic and citric acids. Vitamin C is biologically active as a mild antioxidant and reducing agent and can pass through cell membranes. During pressure cooking, Vitamin C breaks down into several other acids such as dehydroascorbic acid, diketogulonic acid, xylonic acid, threonic acid and oxalic acid. It could be that by being exposed to multiple different acids DMT de-polymerization is improved by complimentary mechanisms.

Other acids may also work, and the kitchen alchemist is encouraged to report on any new experimental results (both positive and negatives).

Cloudiness 🌫️

DMT monomer does not readily form clouds in naphtha. Compared to other extractions that do not minimize polymer, clouds for later in the evaporation process and are not as opaque. This is a good sign and not a cause for concern. It is OK to freeze precipate before clouds are observed after reducing the solvent volume.