Difference between revisions of "Chilled Acetone with IPA and Naphtha"

(→Materials 🛒) |

(→Pull Alkaline Paste 👩🔬) |

||

| Line 42: | Line 42: | ||

== Pull Alkaline Paste 👩🔬== | == Pull Alkaline Paste 👩🔬== | ||

| − | Cover paste with freezer chilled ethyl acetate (~0F), mix | + | Cover paste with freezer chilled ethyl acetate (~0F), mix for for 60 seconds, and filter to a large jar (~64 oz). Repeat 5 times. |

Revision as of 00:38, 9 June 2021

Contents

Introduction 🙏

CIELO stands for Crystals In Ethyl-acetate Leisurely Over-the-counter.

In this technique (TEK), cold alkaline cactus paste (Fig. 2) is extracted with chilled ethyl acetate (Fig. 3). Mescaline citrate is precipitated with citric acid (Fig. 4-5) and collected (Fig. 6).

Thanks to everyone who contributed: someblackguy, Benzyme, shroombee, Metta-Morpheus, Downwardsfromzero, Kash, grollum, Mindlusion, Doubledog, Dreamer042, Loveall, and others.

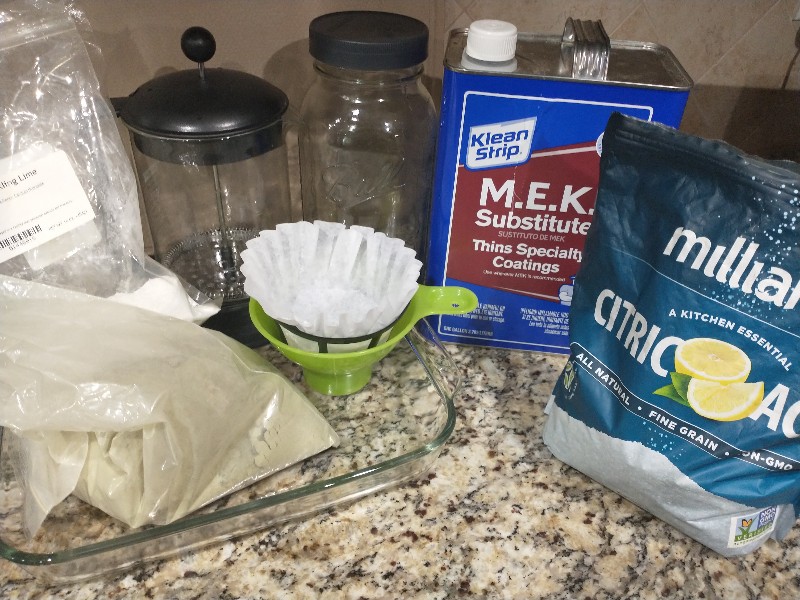

Materials 🛒

- Mescaline Extraction:

- French press

- 300g ice cold water

- 25g lime

- 100g dry cactus powder

- ~Quart of freezer chilled (~0F) ethyl acetate

- Coffee filter, support basket, and funnel

- Large jar (~64 oz)

- ~5g of citric acid

- ~4oz of room temperature ethyl acetate

- Solvent Reclaim:

- Washing soda saturated water

- Separatory funnel or glass turkey baster

Process 📜

Make Alkaline Paste 🌵

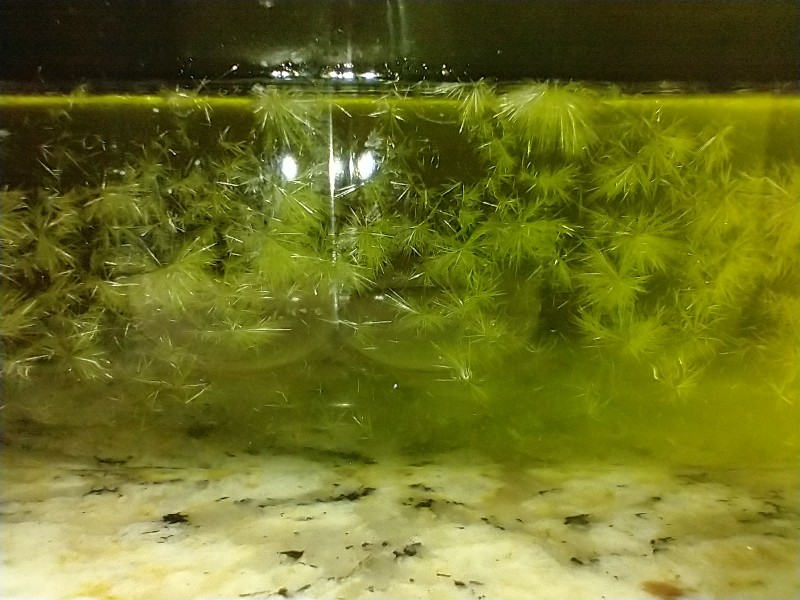

Mix ice cold water and lime in a french press. Stir in cactus powder for a few minutes to a smooth paste (Fig. 2).

Pull Alkaline Paste 👩🔬

Cover paste with freezer chilled ethyl acetate (~0F), mix for for 60 seconds, and filter to a large jar (~64 oz). Repeat 5 times.

Inspect extract for droplets or particles. If present, decant/filter to remove them.

Extract needs to be clean (see Fig. 3).

Crystalize Extract 🧪

Drop (do not stir) citric acid into extract, forming clouds (Fig. 4). After a few hours mescaline citrate crystals form (Fig. 5). Allow crystalization to complete undisturbed (~12 hours).

Collect Crystals ✨

Catch crystals in a coffee filter. Rinse jar/filter with fresh ethyl acetate a couple times and dry (Fig. 6).

If some crystals stubbornly remain on the jar walls, dissolve them in hot water, dry in a shallow dish, and scrape.

Yield is dependent on cactus material and usually between 0.2% to 2% [1] with ~1% being common.

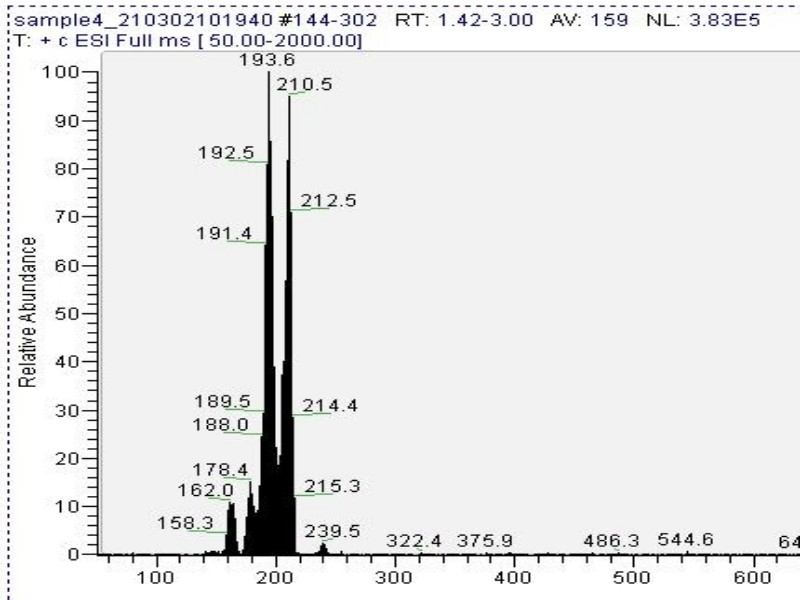

Mass spectrometry (MS) results from solaris analytical[2] indicate the product is very clean mescaline (Fig. 7).

Reclaim Solvent 💚

Reusing solvents is encouraged[3] at the DMT nexus.

Wash spent extract with sodium carbonate saturated water shaking vigorously (emulsions do not form). Citric acid removal is complete when CO2 bubbling stops. Remove water layer. Freeze and filter out ice crystals. Store for reuse.

Appendix: Development Notes 🔬

Paste 🌵

No improvements were seen with longer basing time, microwaving, partially of completely drying (with heat or drying agent), or adding NaCl to increase the ionic strength. The simple cold paste gave the fewest off colors and best crystalization with no yield penalty.

Pull 👨🏾🔬

Longer pull times or higher temperatures the crystalization more difficult with more off colors and with no yield improvement. This is thought to be because of increased plant contaminants.

Short cold pulls also minimize congealing and solvent absorption by the paste.

Extract 🧪

Chemically drying the extract before salting had no yield benefit. Experimentally, the water content in ethyl acetate from the cold pulls is in a good range.

Droplets or debris not decanted/filtered before adding citric acid will result in crystalization issues. It is very important to verify the extract is clean as mentioned in the main TEK.

Crystalization ✨

During crystallization, 233mg of citric acid (H3Cit) react with free base mescaline (Mes) to form to 1g of mescaline citrate (or slightly more if a hydrate is precipitating):

The TEK calls for more citric acid than would be needed for titration because excess citric acid shifts the precipitation reaction to the right (Le Chatelier's principle), helping overcome water and plant material. There is a lot room for excess citric acid in solution since its solubility is 50mg/g in ethyl acetate. The TEK recommends ~5mg/g but since cacti and pull techniques can vary, users may find other values work better for their specific situation (in one example with whole cactus powder 20mg/g was used [4]).

Several factors can make crystals smaller: Reused ethyl acetate, warmer pulls, longer pulls, higher citric acid concentration, and mechanical agitation. Very small needles can look like a fine powder. Potency does not seem affected by the crystallization appearance, and a powdery precipitate is not a problem unless it becomes difficult to decant/filter.

After the initial crystallization, adding more citric acid and/or moving the extract to the refrigerator did not result in any more precipitation. Moving the extract to the freezer produced ice crystals.

Other dry organic acids could work. Fumaric, Malic, Tartaric, Ascorbic, Succinic, etc can be tested in future investigations.