Chilled Acetone with IPA and Naphtha

Contents

Introduction 🙏

In this technique (TEK), potential DMT polymer (also called goo, aggregate, or oligomer) is minimized by (1) pressure cooking with Vitamin C, and (2) using gentle alkaline conditions. By minimizing DMT polymer, a high yielding white crystalize powder is obtained directly from the plant material.

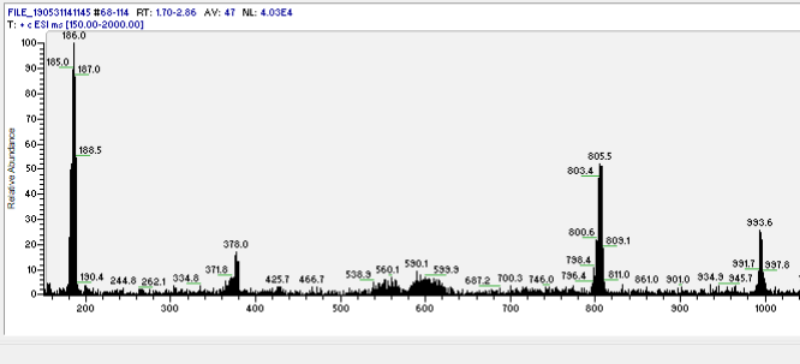

Thanks to Northerner for sharing his excellent pressure cooking experimental result, to Benzyme for showing MS evidence of DMT polymers[1] (see Fig. 1 below), and to Jees, downwardsfromzero, IridiumAndLace, and Loveall for their contributions to this process in the forum.

Safety ⛑️

Review NaOH[2] and naphtha [3] safety information. Verify solvent MSDS purity, plastic compatibility, and clean evaporation.

Never have solvents near an open flame.

Following this advice does not guarantee safety. It is up to each adult individual to make their own decision.

Materials🛒

Consumables👩🌾

- 25g ascorbic acid (vitamin C)

- 50g of mimosa hostlis root bark

- ~775ml water (for canning jar)

- ~A few liters of water (for pressure cooker and warm bath)

- ~250ml naphtha

- 25g of NaOH

Equipment🏺

- Two 1-quart wide mouth canning jars with new lids

- Scale

- Mixing tool (e.g. spoon)

- Pressure cooker

- Sauce pan for warm bath

- Pippette

- Shallow baking dish

- Fan

- Plastic wrap

- Freezer

- Razor blade

Process Overview 👀

- Prepare cook root bark, water, and vitamin C

- Add naphtha and then basify

- Pull, freeze precipate, and collect

Detailed Process 📜

Pressure Cook 🔥💨

Mix, water, vitamin C and root bark in a quart jar. Pressure cook jar at 15 PSI for 4 hours following these instructions:

- Set water level 1 inch from the top of the jar (called headspace)

- Wipe top edge of jar clean before adding lid

- Lid needs to be new and screwed on snug to avoid liquid loss, but not too tight to avoid cracking

- Have a raised platform at the bottom of the pressure cooker and enough water for a 4 hour run

- Prepare jar for pressure by boiling for 10 minutes before adding pressure cooker nozzle weight

- Do not release pressure when run is complete. Instead allow it to slowly drop passively.

If despite following all these instructions the jar breaks or liquid is lost, simply reduce the liquid content of the pressure cooker over heat and transfer it into a new jar. This is added work, so try to avoid it by following canning instructions precisely.

It is OK to pressure cook more than one jar at once and store extras for later extractions thanks to the sterilization and vacuum seal. For such jars, continue the extraction at the next step when convenient.

Pull 👩🔬

Allow pressure cooked jar to cool to room temperature. Break the vacuum seal and shake in ~80ml of naphtha (almost completely filling the jar). Add lye and shake vigorously for 5 minutes. Solution will warm up slightly as lye dissolves, so release pressure from warm naphtha. Heat in warm water bath to 40-50C and shake for another 5 minutes (again, remember to release pressure).

Rest solution in the water bath until naphtha layer separates (~30 minutes). If separation is not complete, mix in another 5g of lye and try again.

Remove naphtha with a pipette or turkey baster into a second quart jar. It is ok if a few drops of watery extract come through (they will be decanted in the next section).

Add another ~80ml of naphtha to the first jar. Get solution back to 40 to 50C using a warm water bath. Shake for 5 minutes (remember to release any pressure buildup). Rest in warm water bath until layers separate, and pippette naphtha into the second jar. Perform this additional pull step 3 times (total of 4 pulls)

Room Temp Option Allow pressure cooked jar to cool to room temperature. Break the vacuum seal and shake in ~80ml of naphtha (almost completely filling the jar). Add lye and shake vigorously for 5 minutes. Solution will warm up slightly as lye dissolves, so release pressure from warm naphtha.

Rest solution until naphtha layer separates (~30 minutes). If separation is not complete, mix in another 5g of lye and try again.

Remove naphtha with a pipette or turkey baster into a second quart jar. It is ok if a few drops of watery extract come through (they will be decanted in the next section).

Add another ~80ml of naphtha to the first jar. Shake for 5 minutes, rest until layers separate, and pippette naphtha into the second jar. Perform this additional pull step two times (total of 3 pulls)

Crystalize ✨

Carefully decant naphtha in second jar to a shallow baking dish. Do not allow any watery extract or particles to come through.

If using new naphtha, evaporate solvent until slightly cloudy with the help of a fan in a well ventilated area. Note that minimum polymer extracts are very soluble in naphtha and tend to cloud less than other TEKs. It is OK if no cloudiness is present after 50% naphtha has evaporated, and the extract can be moved to the freezer at this point. If evaporation is skipped, yield will be lower but more naphtha (containing some DMT) will be available for reuse in future extractions. Used naphtha does not need to be evaporated before freezing since it is already comes with a DMT content that is saturated at the freezing temperature.

Cover shallow baking dish with plastic wrap and place in the freezer for at least 24 hours so DMT crystals form.

Decant naphtha off crystals, and immediately dry baking dish with the help of a fan. Keep dish tilted in the same direction after decanting to avoid warm naphtha residue from washing over crystals.

Once dry, scrape up dry xtals with razor blade. Avoid bottom edge if oily. This is the final product.

Reclaim Solvent 💚

Reusing solvents is encouraged[4] at the DMT nexus.

Simply reuse freeze precipitated naphtha as-is. Re-used naphtha is saturated with DMT at freezer temperature and pre-freezer evaporation is not needed. Easy 😊

Frequently Asked Questions ❓

Q: That's a lot of hypothesis you got down in the appendix. Have any experimental evidence consistent with them?

A: Yes. Benzyme's MS, together with polymerization and de-polymerization experiments. As far as we know experiments are consistent with the hypotheses listed. The community is welcome to update this Wiki entry as more evidence arises, especially if any of the hypotheses are disproved (thank you).

Q: What's so special about Vitamin C?

A: See the development notes in appendix below.

Appendix: Development Notes 🔬

Hypotheses 🤔

This TEK hypothesizes that:

- Not all of the DMT is in the plant in monomer form, some of it is in macro-molecule form (also called polymer, oligomer, or goo)

- In addition to natural DMT polymer, even more polymer can form during the basing step under high alkaline, high ionic strength, and high DMT concentration conditions

- A pressure cooker treatment of the bark using vitamin C is effective at breaking down any natural DMT polymer to the monomer form

- DMT monomer compared to DMT polymer:

- Easier to dissolve in naphtha (better partition coefficient)

- Clouds later during naphtha evaporation

- Slowly crashes during freeze precipitation as white crystals. In contrast, DMT polymer precipitates sooner as yellow/orange/red semisolid goo

- Easier to handle and dose precisely

- Low and consistent vaporization temperature, ideal for newer electronic vaporization devices with precisely tuned temperature settings

- Visibly unique upon crystalization, eliminating questions around plant oil contaminants

- May be easier to complex with HPBCD for sublingual administration

- It is unknown if it has better bioavailability for oral or rectal administration. In principle, stomach acid should be able to break down DMT polymer, so perhaps there is no difference for oral administration

- There is no expected benefit for torch vaporization by an experienced user since the strong heat produced manually can easily vaporize everything. However, the process window between vaporizing and burning the DMT is larger for the monomer which may benefit the inexperienced user

Strategy ♟️

The strategy of this TEK is to break down both DMT aggregates and plant material, while minimizing DMT re-aggregation during the basing step.

Agressive alkaline concentration conditions are avoided. While these type of processes can break down plant material, their downside is that they don't break down natural DMT aggregates and can even increase the degree of polymerization.

Fortunately, DMT aggregates can break down in acidic conditions. Therefore, to simultaneously break down DMT aggregates and plant material, a long acidic pressure cooking step is used (described before by for example Northener). Vitamin C is chosen as the source of acid due to its good experimental performance, but other acids could also work. Subsequently, relatively gentle ionic strength (no added salt), alkaline pH (no excess lye beyond emulsion breakdown), and low DMT concentration (<0.5%) conditions are used to minimize any DMT re-aggregation. Naphtha is also present during the basing step to minimize the time DMT spends in alkaline water when it is at its highest initial concentration.

Vitamin C 🍊

Experimentally, Vitamin C produced better results compared to acetic and citric acids. Vitamin C is biologically active as a mild antioxidant and reducing agent and can pass through cell membranes. During pressure cooking, Vitamin C breaks down into several other acids such as dehydroascorbic acid, diketogulonic acid, xylonic acid, threonic acid and oxalic acid. It could be that by being exposed to multiple different acids DMT de-polymerization is improved by complimentary mechanisms.

Other acids may also work, and the kitchen alchemist is encouraged to report on any new experimental results (both positive and negative).

Cloudiness 🌫️

DMT monomer does not readily form clouds in naphtha. Compared to other extractions that do not minimize polymer, clouds form later in the evaporation process and are not as opaque. This is a good sign and not a cause for concern. It is OK to freeze precipate before clouds are observed after reducing the solvent volume by ~50% or more. Re-using naphtha avoids this complication since it is already saturated with DMT at the freezer temperature (no naphtha evaporation is needed).