CIELO

Contents

Introduction

CIELO stands for Crystals In Ethyl-acetate Leisurely OTC (Over The Counter).

In this TEK, aqueous cactus paste is broken down with microwave radiation, basified with lime, made clumpy with CaCl2, and extracted with ethyl acetate. The extract is salted with citric acid to precipitate mescaline citrate crystals directly in the solvent.

Materials

- Quart jars with LDPE or PP plastic lids (e.g. below)

- Food scale

- 300g water

- 100g powdered dry cacti

- Microwave

- 25g Ca(OH)2 (lime)

- 25g anhydrous CaCl2

- ~ 1000g ethyl acetate ("MEK substitute")

- pH paper

- Citric acid

- Filter (optional)

- Shallow baking dish

- Scraping tool (e.g. razor blade)

Safety

Review ethyl acetate's safety information[1] and check the manufacture's MSDS to verify you have pure ethyl acetate.

Each adult individual needs to find and review any other relevant safety information throughly and make their own personal decision on proceeding.

Process

Paste

Mix water and cactus powder in a a quart jar. Microwave in short bursts, interrupting the irradiation so the paste does not swell over the rim. This can get to be only a few seconds, so patience is required. Stir frequently and keep track of evaporation with a food scale. Paste color will change from green to tan. Once ~55g of water evaporate microwaving is complete.

Mix in lime until homogeneous and then mix in CaCl2 until paste breaks up into spongy clumps.

With a little practice this step can be done in under an hour. See image below from initial green water paste and final clumpy tan paste.

Pull

Add ~ 200g of ethyl acetate to the paste making the jar ~3/4 full and seal with proper lid. Extract for at least 20 minutes regularly shaking every once in a while. Allow to rest and settle for at least 15 minutes and decant to a second jar.

Pull three more times. Progress can be monitored with pH paper (green color indicates free base presence -see image bellow). Paste will change during the pulls and become gunky. When working with a gunky paste, stir, don't shake.

Combined pulls will give ~a quart of clear yellow extract (see image below). Optionally, more pulls can be done into a different jar for a modest yield improvement.

Salt

Dissolve ~250mg (~1/16 tsp) of citric acid into the extract making it cloudy. Test with pH paper. Salting is complete when pH paper is acidic. If needed, add more citric acid in small increments of ~100mg.

Place extract in fridge to fully crash mescaline citrate crystals over 12-72 hours. Precipitation is complete when salted extract goes from cloudy to clear.

If crystals do not form after a few days there was an issue with the TEK. A freezer precipitation can be tried. If that doesn't work either, it should still be possible to recover any product in the solvent with water pulls followed by evaporation and ethyl acetate washes.

Finish

Decant ethyl acetate into a storage jar for reuse, using a filter to catch any loose crystals. Rinse crysals with fresh ethyl acetate at least once or until yellow color is removed to personal cosmetic satisfaction. Dissolve crystals in minimal warm water and passively evaporate undisturbed in a shallow baking dish. Finally, scrape up the resulting long crystal needles.

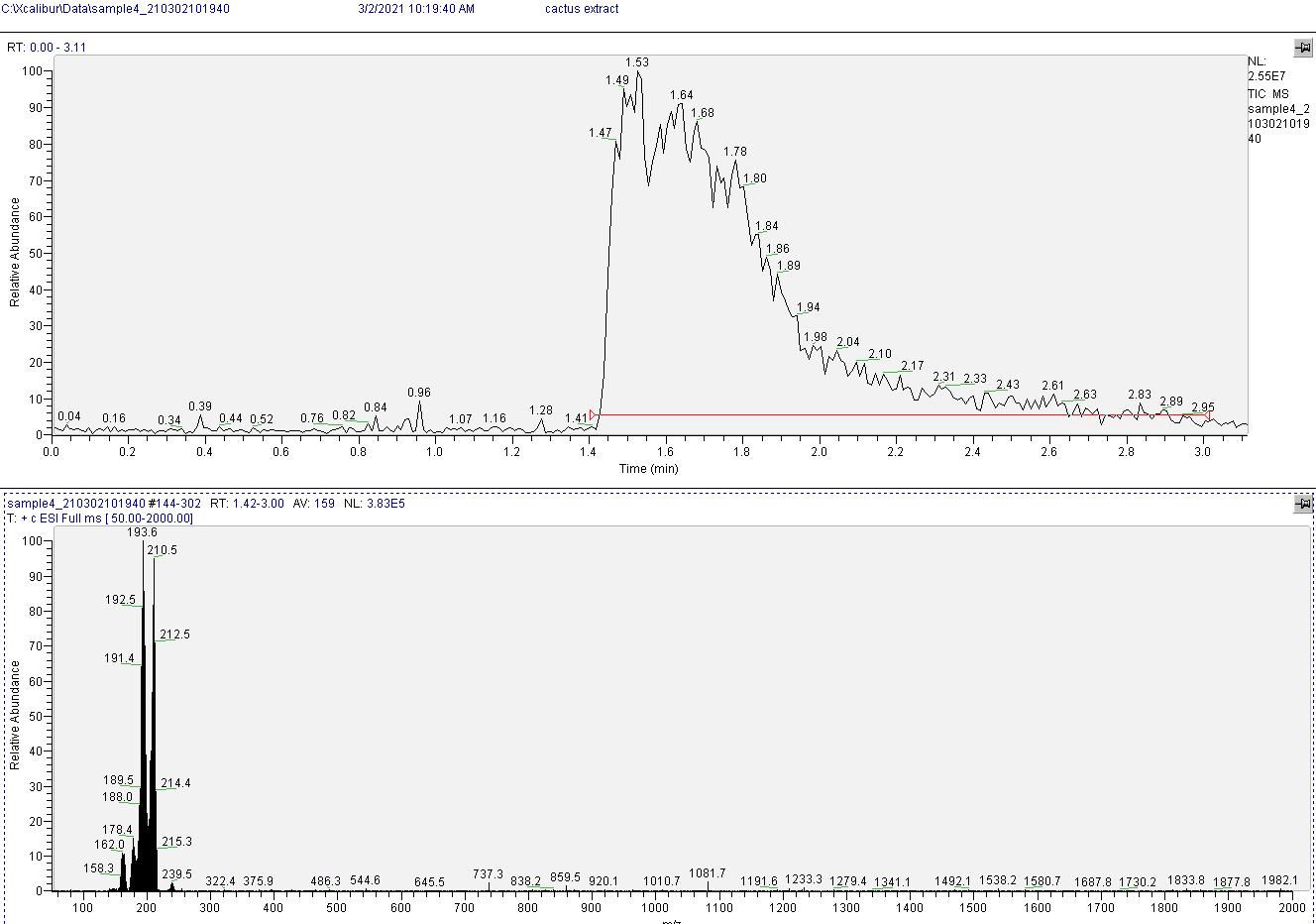

Mass spectrometry results indicate the product is very clean mescaline. See image below, peaks near 210 and 194 are both from mescaline (lower mass peak is from amine cleavage).

Lab Notes

The microwave radiation breaks down the plant matter potentially helping free mescaline from the biological matrix. CaCl2 improves the paste texture and helps keep water out of the solvent. CaCl2 can lower the pH by making Ca(OH)2 less soluble, however a test 250g water solution with 25 of Ca(OH)2 and 25g of CaCl2 had a pH of 11.1, above mescaline's pKa of 9.6. Overall, the resulting plant paste seems to give give efficient and clean pulls that are ready to to crash the mescaline salt. Different paste process order, skipping the microwave, using NaCl instead of CaCl2, or using acetone instead of ethyl acetate, could work too, but may have lower yields, produce a less workable paste, or carry unwanted plant matter that interferes with crystalization or ends up in the product.

Allowing 8 hours rest before decanting gives the pull enough time for ethyl acetate, water, and cactus/Ca(OH)2/CaCl2 time to settle and reach liquid-liquid equilibrium.

It is possible to chemically dry the extract with a drying agent such as anhydrous MgSO4. However, no clear yield benefit was observed by performing this step. Surprisingly, solutions carefully dried with anhydrous CaCl2 followed by K2CO3 had difficulty crystalizing after salting, indicating that a some water is desirable for crystalization. This points to the precipitate from this TEK maybe being hydrate salt. Regardless if the reason, the water content in ethyl acetate directly from the pulls is in a good range experimentally.

During salting, every 10mg of citric acid (CitH3) reacts with enough free base mescaline (Mes) to precipitate up to 43mg of mescaline citrate (or slightly more if a hydrate form is precipitating):

250mg of citric acid are enough for the typical cactus (up to 1% yield). However, and outlier like the legendary Ogun would need ~1100mg of citric acid for a 4.7% yield.

Over acidifying is not a big concern. There is room for excess citric acid in solution since several grams can dissolve in a quart of ethyl acetate even when chilled. The vast majority of excess acid would be poured off after salting, and any traces removed when washing the crystals.

Other solid organic acids could work. Fumaric acid was tested and gave wispy tiny crystals (not ideal). Malic was tested and slowly crystalized from a dry solution. Tartaric could not crystalize well from dry a dried extract, but began to crystalize with some water added (similar to citric acid). There are many other solid organic acids soluble in ethyl acetate that can be tested (ascorbic, succinic, etc).

It is possible that some of the assumptions and conclusions in these lab notes are incorrect or incomplete. The process was simply tuned for good yields, but the search was not exhaustive[2]. There could be ways to improve this process.