Difference between revisions of "CIELO"

(→Safety) |

(→Introduction) |

||

| Line 1: | Line 1: | ||

| − | = Introduction = | + | = Introduction 🙏= |

'''CIELO''' stands for '''C'''rystals '''I'''n '''E'''thyl-acetate '''L'''eisurely '''O'''ver-the-counter. | '''CIELO''' stands for '''C'''rystals '''I'''n '''E'''thyl-acetate '''L'''eisurely '''O'''ver-the-counter. | ||

Revision as of 12:48, 6 June 2021

Contents

Introduction 🙏

CIELO stands for Crystals In Ethyl-acetate Leisurely Over-the-counter.

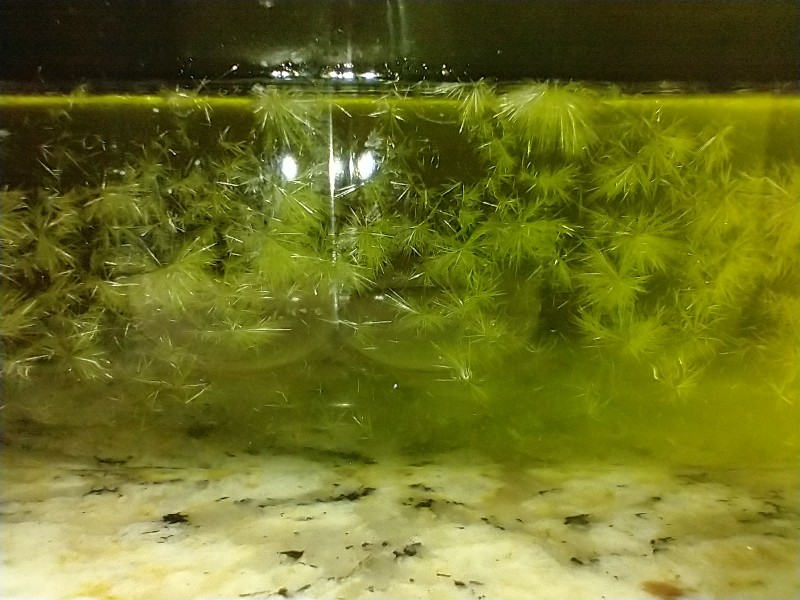

In this technique (TEK), aqueous alkaline cactus paste (Fig. 2) is extracted with chilled ethyl acetate (Fig. 3). Citric acid precipitates crystals in the extract (Fig. 5) and the mescaline citrate is collected (Fig. 6).

This TEK was developed in a loving collaboration at the DMT nexus. Deep thanks and gratitude go to everyone who contributed: someblackguy, Benzyme, shroombee, Metta-Morpheus, Downwardsfromzero, Kash, grollum, Mindlusion, Doubledog, Loveall, and others.

Safety ⛑️

Review ethyl acetate's safety information[1]. Verify MSDS, plastic compatibility, and clean evaporation.

Following this advice does not guarantee safety. It is up to each adult individual to make their own decision.

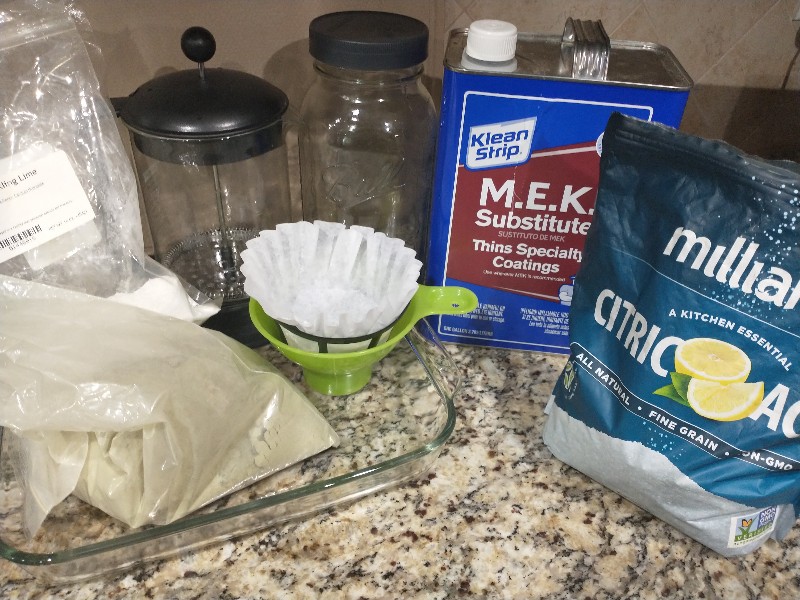

Materials

- Mescaline Extraction:

- Quart jar or french press

- 300g water

- 25g lime

- 100g dry cactus powder (outer skin or whole cactus)

- ~1200g ethyl acetate

- Paper coffee filter, support basket, and funnel

- Large jar (~64 oz)

- 5g of citric acid if using outer cactus skin or 20g if using whole cactus

- Shallow baking with lid and aluminum foil

- Razor blade

- Solvent Reclaim:

- Washing soda

- Water

- pH paper strips (optional)

- Separatory funnel or glass turkey baster

Process

Make Alkaline Paste 🌵

Mix water and lime in a quart jar or french press. Incorporate cactus while stirring and continue stirring for at least 10 minutes to a smooth paste.

Pull Alkaline Paste 👩🔬

Add ~ 300g of freezer chilled ethyl acetate (~0 F) to the paste, mix thoroughly for for 60 seconds, and decant/filter to a large jar (~64 oz). If using a french press squeeze very gently or not at all to avoid pulling water. Immediately pull 5 more times with ~150g of ethyl acetate stirring thoroughly for 60 seconds each time.

Inspect extract for droplets or particles. If present, decant/filter to remove them.

Extract needs to be clean (see Fig. 3).

Crystalize Extract 🧪

Let extract reach room temperature and pour it into a shallow baking dish. Gently drop in 5g of citric acid if using outer skin powder or 20g if using whole cactus powder. Do not stir, simply allow citric acid to diffuse into solution forming clouds (Fig. 4).

Cover with a protective layer of aluminum foil and plastic lid (most shallow baking dish lids are not resistant ethyl acetate). After a few hours clouds crash as mescaline citrate crystals on the walls (Fig. 5). Allow enough time to complete crystallization (~24h is typically sufficient but can vary).

Collect Crystals ✨

Decant and rinse crystals with a small amount of fresh ethyl acetate twice. Allow crystals to dry and collect them from the shallow baking dish with a razor blade. This is the final product (Fig. 6).

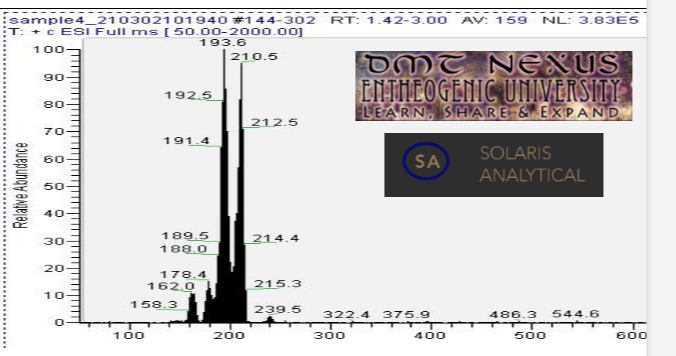

Mass spectrometry (MS) results from solaris analytical[2] indicate the product is very clean mescaline (Fig. 7). Yield is highly dependent on cactus material, usually between 0.2% to 2% [3].

Reclaim Solvent 💚

Wash spent extract with sodium carbonate saturated water shaking vigorously (emulsions do not form). Citric acid removal can be optionally checked with a strip of pH paper. Separate and store washed ethyl acetate for reuse.

Reusing solvents is encouraged[4]

Appendix: Development Notes

Paste

No improvements were seen with microwaving, partially drying with heat or a drying agent, adding NaCl to increase the ionic strength, or extending the reaction time beyond 24h. Completely drying the paste made the process not work.

Pull

It is also possible to obtain good results with 3 minute room temperature pulls (30s of stirring and 150s of rest), but the results may not be as consistent compared to chilled ethyl acetate (60s of stirring). This is thought to be because of increased plant contaminants in the warmer pull at room temperature.

Long room temperature pulls made the paste congeal and resulted in lower yield. Heating during the pull did not improve yields. Generally, longer times or higher temperatures make the crystalization more difficult without yield improvements. Also, a persistent tan color can contaminate the product.

Extract

Chemically drying the extract with a drying agent such as anhydrous MgSO4 before salting had no yield benefit. In one example, drying the extract with CaCl2 resulted in a more difficult crystalization and a 40% yield loss. In general, any water content in ethyl acetate directly from the pulls is already in a good range experimentally.

Droplets or debris not decanted/filtered before adding citric acid will result in crystalization issues. It is very important to verify the extract is clean as mentioned in the main TEK.

Crystalization

During crystallization, every 10mg of citric acid (H3Cit) reacts with free base mescaline (Mes) to form to 43mg of mescaline citrate (or slightly more if a hydrate is precipitating):

The TEK calls for a more citric acid than would be needed for titration. The reason is that excess citric acid shifts the reaction to the right, helping overcome any water or plant material that would otherwise keep mescaline citrate in solution (Le Chatelier's principle). There is a lot room for excess citric acid in solution since its solubility is 50mg/g in ethyl acetate. The TEK recommends 5mg/g for outer skin cactus powder and 20mg/g for whole cactus powder based on early experiments[5], but some users may find better values for their specific plant material and pull temperature/time.

Other dry organic acids could work. Fumaric, Malic, Tartaric, Ascorbic, Succinic, etc can be tested in future investigations.

Disclaimer

It is possible that some of the assumptions and conclusions in these lab notes are incorrect or incomplete. The process was tested in several ways, but the search was not exhaustive. There could be ways to improve this process.